The creation of an effective system of the control of oil and its processing products movement from a cavity to a final consumer is impossible without the organization of trustworthy evaluation of the prospected oil in the content of the obtained oil-gas-water composition (OGWC).

The main problems that have the greatest impact upon the accuracy of prospected oil quantity estimation are:

- the content and structure of OGWC estimation object that is characterized by special and time changeability;

- the diversity of the estimated environment that is defined by qualitative characteristics - density, viscosity, sodium content, etc., and also by the diversity of numeral characteristics, such as daily debit, gas factor, watering, etc.

- a lack of complex methods of the implied estimation means check-up on exploitation objects and metrological characteristics control methods;

- a lack or insufficient level of standard and experimental basis for OGWS estimation means;

- a lack of typical solutions on the implementation of approved estimation methods and means to specific exploitation conditions.

The existing unsatisfactory condition in the area of prospected oil estimation provision in the content of prospected OGWC leads to unjustified risks and, first of all, under the control organization by state institutions:

- the correct definition of the taxed base on the prospected minerals tax (further - PMT);

- a rational usage of subsoil and realization of licensed agreements on deposits´ prospecting;

- an observance of a cavity work regimen;

- in order to prevent possible thefts and malusage;

- in order to prevent accidents and technological regimen violations concealment, that lead to oil overflow and negative impact upon the environment.

Realization of new technologies with usage of high-quality components, specialized automated systems that preclude a human factor impact and allow us to provide the estimation unity on every stage of prospecting, transportation, storing, processing, and realization of oil.

The system of oil quantity and quality estimation (SOQE) is designed for the estimation of oil net mass, technological and qualitative oil characteristics, and also for indication and registration of the obtained estimation results.

As shows the analysis of domestic and foreign means of oil content estimation in OGWS, nowadays there are no such estimation methods that fully correspond to all requirements of obtaining trustworthy cavity estimations [1]. A high diversity of OGWS as an estimation object makes it impossible to create a single universal estimation technology. Here an extremely urgent objective is to establish the requirements and selection of a basic technology that corresponds to the most widespread cavity type, along with a simultaneous registration of modern condition of the modern multi-phase estimation metrological provision system [2].

In terms of lack of initial standards and check schemes for unseparative estimation facilities makes it more effective to use systems that implement separative methods on the current stage:

To create SOQE it is supposed to ude:

- mass flow meters;

- intellectual temperature indicators and thermometers;

- redundant pressure indicators and monometers;

- net filters with quick-detachable lid;

- wedgebar bolts (or globe taps) as a shut-off fixture;

- consumption calculators;

- software for SOQE automated workplace.

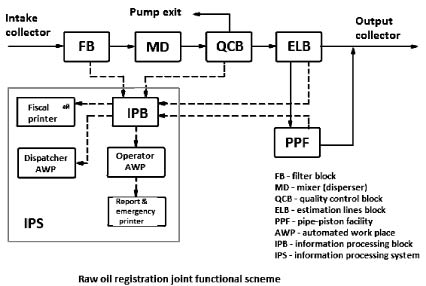

Functional system of raw oil registration joint, provided in Figure includes:

- filer block (FB);

- mixer - disperser (MD);

- quality control block (QCB);

- estimation lie block (ELB);

- pipe-piston facility plug joint (PPFP);

- information processing block (IPB);

- information processing system.

In accordance with recommendations, a filter block must include no less than two parallel working filters: operative and reserve that allows us to turn off any of them for a cleaning without raw oil registration joint (RORJ) workflow disturbance. On each filter a differential pressure transformer is installed in order to control filter elements obstruction. Shut-off fixture is also implied (4 bolts) that helps to turn off each filter individually.

The estimation line block (ELB) includes:

- intake and discharge collector;

- operative, reserve, and control line;

- shut-off fixture;

- oil drainage system.

ELB is mounted on the operational frame and constructively consists of three estimation lines (two operative and one reserve), each of which is equipped with mass consumption meters (or turbine consumption transformers), pressure and temperature indicators, monometers, and thermometers. On the exit of each estimation line a shut-off fixture with leakage control is installed. The number of estimation lines is dependent on the operative consumption and product viscosity, and is defined on the project works stage after obtaining a project objective.

Quality control block is suggested to use with the following components:

- automated and manual oil sampler;

- consumption indicator;

- densimeter;

- raw oil moisture gauge;

- cavity sampler;

- monometer and pressure indicator with an output current signal;

- thermometer and temperature indicator with an output current signal;

- fluid consumption indicator through QQB;

- fluid consumption regulator;

- shut-off fixture for plugging a free gas definition facility.

In difference with commodity oil registration joint in RORJ a mixer, or disperser is foreseen, its purpose is to prepare a homogeneous mixture out of water-oil flow.

To compensate thermal losses while work product swapping, it is possible to implement a piping heating system on the basis of heating cables. In this case all the SOQE pipe necking is covered by a heat insulation with an outer aluminium jacket.

On the whole, all domestic estimation facilities realize a number of technological solution types of OGWC that differ in content, functions, and estimation methods.

Nowadays the most widespread because of historical causes have the estimation facilities that estimate OGWC on a cavity mouth by the method of separated liquids and gas with help of simple single-phase estimation utilities that are installed on output pipes for gas, oil, and water of two- or three-phase separators. In Russia theses facilities that are analogues of foreign «separators for test exploitation» are placed on the most of enterprises and are connected by a collector or a distribution valve with a number of cavities. Their replacement with new utilities is extremely slow.

To define an oil watering percent in an estimation facility a moisture gauge is placed through which all the cavity production is passed.

The most widespread is one of indirect methods of oil watering estimation that is based on the dependence of dielectric water mixture penetrability on dielectric characteristics of its components (oil and water). Waterless oil is a good dielectric and has dielectric penetrability ε = 2,1-2,5, while dielectric penetrability of mineralized waters equals ε = 80. Such difference in oil and water dielectric penetrability makes it possible to create a moisture gauge of a relatively high sensitivity. The action principle of such moisture gauge is condenser capacity estimation that is formed by two electrodes, placed in an analyzed water-oil mixture.

A unified moisture gauge of such type for oil (UMO) allows us to permanently control and register a volume water content in an oil stream with a inaccuracy of 2,5 to 4 %.

For more accurate water content estimation it is necessary to avoid gas bubbles placement on the sensor, as it has low dielectric penetrability that can be compared to oil (ε = 1), and a liquid stream before it reaches sensor should be carefully mixed until the mixture is homogeneous, as the more homogeneous a stream is, the higher a utility indication accuracy.

The following factors have significant impact on layer water and oil content estimation by this utility:

1) OGWC temperature alteration;

2) mixture homogeneity degree;

3) gas bubbles content in a liquid stream;

4) electric field tensity in sensor.

A moisture gauge sensor is placed vertically and must let through all liquid (oil and water) cavity production.

We have studied relative characteristics of domestic and foreign means and methods of oil content in OGWC. The data analysis shows us that practically all modern estimation facilities characteristics are close. This circumstance is explained by the fact that all utilities´ producers claim characteristics that are correspond to regulatory and legislative documentation requirements as maximum as possible. Nevertheless, with a lack of initial standards, approved control schemes, metrological characteristics control methods in an exploitation conditions there is no trustworthy method to affirm the claimed characteristics. Under such terms characteristics, declared by manufacturers can form the basis for analysis and development of suggestions of preferable technologies for oil content in OGWC

estimation.

References

- Kratirov V.A., Gareyev M.M. Some aspects of implementation of new means for oil consumption estimation considering its phase condition data // III Russian oil-and-gas producers conference work program. - Ufa: Transtech, 2001.

- Letton V., Swaren J., Konort J. Multi-phase consumption meters usage experience on the side of a cavity mouth and under water, article of SPE 38783. Annual technical conference and exhibition of SPE. - San-Antonio, Texax, 5-6th of October 1997.