For alcoholic beverages, the most frequent cases of technological falsification of drinks by replacing natural raw materials (fruits, herbs, roots, sugar, etc.) with synthetic dyes, flavors, sweeteners, glycerin, as well as replacing high-quality alcohol recommended for consumption with cheaper ones [1]. This is done in order to reduce production costs and, as a result, increase net profit. However, in such activities, testing for suitability for consumption is often neglected, and as a result, drinks that have not been properly tested and do not meet standards end up on store shelves. The use of such drinks, in addition to the inconsistency of the taste characteristics, can also lead to poor health, food poisoning, and also, in some cases, lead to death. That is why the identification and falsification of alcoholic beverages is a serious problem [1].

Purpose of the study. Research was carried out in order to study the methods used for identification and examination of strong alcoholic beverages, to determine their shortcomings and to adapt alternative methods to objectify the identification process.

Materials and research methods

The existing methods of control of alcoholic beverages, established by GOST 32035-2013, include determination of [2]:

- organoleptic characteristics;

- fullness of filling;

- the volume fraction of ethyl alcohol;

- the mass concentration of methyl alcohol;

- the mass concentration of aldehydes;

- the content of toxic trace impurities;

- the mass concentration of esters;

- the mass concentration of furfural;

- the mass concentration of iron;

Organoleptic indicators include:

- appearance;

- transparency;

- aroma and taste;

- color [3].

The parameters of color and transparency are determined visually in the light when comparing the test product andpure distilled water, aromatic and taste characteristics are determined by the organoleptic method. In appearance, the test product should be a clear liquid without extra inclusions and impurities, without color. The degree of clarity of hard alcohol is described as clear, clear with a sheen, just clear, clear without a sheen, and hazy. For pure vodka without flavor additives, the appearance of shades of different colors is unacceptable, as this is an indicator of a violation of the technology for preparing the product or the fact of its falsification. Aroma – must be typical for this type of alcoholic beverage without foreign smell. When talking about the aroma of strong alcoholic products, they mean the smell characteristic of this type of alcohol, on which strong alcoholic products are prepared. The product formulation must specify and describe the specific aroma characteristic of the product. The bouquet is a complex combination of notes and shades of the aroma of the drink, which develops during its aging.

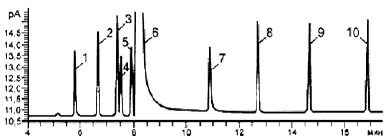

Fig. 1. Chromatogram of the analysis of the calibration mixture obtained on a chromatograph equipped with an HP-FFAP capillary column: 1 – acetaldehyde; 2 – methyl acetate; 3 – ethyl acetate; 4 – methanol; 5 – 2-propanol; 6 – ethyl alcohol; 7 – 1-propanol; 8 – isobutyl alcohol; 9 – 1-butanol; 10 – isoamyl alcohol

The taste for pure vodka should be typical for this type of product and should not have foreign flavors typical for this type of vodka without foreign flavors. Vodka should have a mild, unique taste. A sharp or sharp taste, as well as an uncharacteristic aftertaste, are indicators of the poor quality of vodka [3].

The method for determining the presence of hazardous substances and impurities is described in state standard GOST 30536-2013. It applies to products from ethyl alcohol made from food raw materials and describes the method of gas chromatographic (Fig. 1) determination of the content of impurities using capillary columns, the presence of which is characteristic of strong alcoholic products and ethyl alcohol. The method is suitable for the determination of toxic trace impurities in special vodkas and in distillates obtained from alcoholic beverages [4].

The range of measured volume fractions of methyl alcohol is from 0.0001 to 0.1%, the mass concentrations of other toxic trace impurities are from 0.5 to 1000 mg/dm3. The method is based on chromatographic separation of trace impurities in a sample of alcohol or strong alcohol and their subsequent detection with a flame ionization measurer. Gas-liquid chromatographs and gas chromatography-mass spectrometers equipped with a mass spectral data bank, allow in a few minutes to carry out a complete analysis of a drink for the presence of various organic impurities in it, including components of fusel oils, methyl alcohol, ketones, aldehydes and other compounds. However, such an analysis is possible only in specialized laboratories with special, rather expensive equipment and highly qualified personnel. Currently, this method has been introduced into the current standard [1,4].

Research results and their discussion

The methods of certification and examination of strong alcoholic beverages used today for compliance with the current technical regulations and standards are labor-intensive processes that require the participation of highly qualified specialists, and they are impossible without opening the container and taking samples. Therefore, in order to optimize, accelerate and the possibility of carrying out continuous express control, it is proposed to adapt the method of express analysis of liquid packaged products [5] for strong alcoholic beverages, incl. together with the method for determining the type of liquid by characteristic frequencies [6].

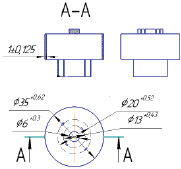

Measurements with the help of a double coaxial sensor of two capacities and two loss angle tangents make it possible to calculate the average value of the relative permittivity (ε) of a strong alcoholic beverage, and in the presence of standard data (τe, ηe), – determine the dynamic viscosity of the sample (η0) by calculating its microscopic (τ0) and macroscopic relaxation time (τ) [5-7]:

ε = С0 / Са

η0 = τ0ηе / е

τ0 = 3ετ0 / (2ε + 1)

tgδ = (ε – ε∞)ωφ / (ε + ω2τ2)

Cа – capacitance of the sensor cap in air; С0 – the capacity of the sensor cap with a strong alcoholic beverage; η0 – dynamic viscosity; τ и τ0 – relaxation times (macroscopic and microscopic respectively); ω – cyclic frequency; ηэ и τэ – tabular air data loaded into the computer.

Fig. 2. Capacitive 2-electrode coaxial sensor-cap

Determination of the required parameters is carried out using emittance meters E7-29 (in the SAС) and E7-25 (in the PAС), which have the required accuracy classes and frequency ranges. E7-25 and E7-29 immitance meters are devices with a high accuracy class of 0.1. It has a operating frequency range of 25 Hz – 1 MHz [8, 9]. The principles of operation of the devices are based on the ammeter-voltmeter method. The immittance characteristics of the object under study are converted into a primary voltage directly proportional to the current that passes through the object itself, simultaneously with the primary voltage and into the voltage of the object itself (secondary). The ratio of the resulting voltages equals the resistance and conductivity of the object [8, 9]. The measurement of the voltage ratio and the calculation of the immittance characteristics are carried out using microprocessors [8, 9].

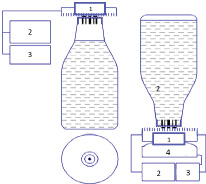

The essence of the method for determining the type of liquids for strong alcoholic beverages [6] is as follows: the specific active electrical conductivity of the liquid is measured in the range of 0.001–10 MHz for two different temperatures between the boiling and freezing temperatures of the liquid, and by the intersection of the dependences of the specific active electrical conductivities on the frequency of oscillations of the electromagnetic field, one finds the characteristic oscillation frequency, which can also be used as one of the main criteria for determining the type and quality of the liquid in the system being developed [6, 10].Devices LQtest 2.8 and Kolos-2 are used during testing of models of SAС and PAС, for verification of dielectric constant and density of samples [11, 12].

The LQtest 2.8 portable safety device is designed to detect hazardous liquids in closed vessels such as plastic and glass bottles, cardboard bags and other non-metallic containers [11].

Liquid analyzer “Kolos-2” is an ultrasonic device designed to measure the concentration of substances in liquid media, incl. containing ethyl alcohol, as well as products of the brewing, wine, alcoholic beverage industry, and on the basis of the measured values - the calculation of the characteristic indicators of the composition of the sample. The principle of operation of the analyzer is based on the fact that ultrasonic vibrations are passed through the sample and the ultrasound parameters are recorded, which characterize the concentration of substances and the temperature of the sample [12, 13].

The model of a system for continuous monitoring of strong alcoholic products [6, 8, 10] (Fig. 2) is presented in two variants of a set of subsystems:- subsystems of distributors and users of alcoholic beverages, consisting of a portable complex (PAC) with specialized equipment, including: a laptop with pre-installed software necessary for collecting and processing measurement results, an immitance meter and an electronic balance with a contact pad for various container caps-sensors, which clog alcoholic beverages;- subsystems of the manufacturer of alcoholic products on production lines, which, in order to ensure the quality and protect products from counterfeiting, have developed and applied a special sensor cover with contacts brought out to the outside,and organized continuous control of the manufactured packaged products after capping, using a stationary automated complex (SAС) and placing on the Internet “images of standards” of produced alcohol, which are “downloaded” in the PAС [6].

Fig. 3. Model PAС system of continuous control (SA differs in the use of E7-29 and PC). 1 – switch; 2 – immittance meter E7-25; 3 – laptop; 4 – electronic scales with a temperature sensor

It is possible that in order to determine the water content in alcoholic beverages, at the next stage of research in special software SAC and PAC, algorithms for determining the mass fraction of water in alcoholic beverages from RF patent No. 2192001 will be used [14].

Conclusion

The existing problems for this area are identified and analyzed, the existing methods and means for determining the parameters of packaged strong alcoholic products are described, as a result of which it is concluded that at the moment standard methods and means are not able to provide an adequate level of control of packaged alcoholic beverages and other strong alcohol. alcoholic products. An adaptation of the liquid identification method by weight impedance electrometry described in patent No. 2696810 and No. 2383010, with the use of an immittance meter E7-29 by the manufacturer, and in the PAK – E7-25, with the verification of the dielectric constant by the safety device LQtest 2.8, and density – with the analyzer of liquid media “Kolos-2”.