The relevance of this topic and its relevance is substantiated by the results of domestic and foreign researchers, who showed that, for example, in Russia and Latin America, the share of illegal alcoholic beverages in the consumed alcoholic beverages is 28.5% [1].

Industrial and food liquid products are poured, as a rule, by automatic lines and devices into various containers (polymer, glass, cardboard, etc.). At the same time, most manufacturers of both industrial, grocery and household liquid packaged products practice mechanical means of protecting their products from counterfeiting, for example, using branded containers, sealing the necks of packaging containers with foil. Some enterprises develop and produce original containers (bottles, canisters, etc.) and “destructible lids”, as well as use holographic stickers, etc. However, the volume of counterfeit products is not decreasing.

So, for example, the results of the inspection of Rospotrebnadzor for 2020 showed the following [2]:

- 796 violations were detected at 462 enterprises producing alcoholic products, for which 974 Protocols on administrative offenses were drawn up, incl. for 1 packaged product with a fake excise stamp and for 1 unmarked product;

- 3310 violations were revealed at 1965 wholesale trade enterprises, for which 4296 Protocols on administrative offenses were drawn up, incl. for 9 packaged products with fake excise stamps and 4 unmarked ones;

- 983 violations were revealed in 1701 retail trade organizations, for which 1129 Protocols on administrative offenses were drawn up, incl. on 7 packaged products with fake excise stamps and on 33 unmarked products.

The amount of alcoholic products that were seized and destroyed was about 328,771 units [2].

It is essential that the certification and examination of liquid packaged products (for compliance with current technical regulations and standards) are long and laborious processes, and they are impossible without opening the container.

As part of the decision of the State Council on the creation of a National System for Protecting Consumers from Counterfeits, effective and inexpensive express methods for monitoring parameters are being developed and adapted, which can be used at the enterprise (integrated into automated lines) and also at points of sale (have mobility) [3].

This indicates that the existing methods of control and supervision are not effective, both in terms of identifying alcoholic products and protecting consumers from counterfeiting. In other words, the scientific and technical problem of identifying such products arises, in connection with which, in this article (on the example of packaged beer products), a model of an automated control system is proposed that allows detecting low-quality products and / or counterfeit goods in order to withdraw it from sale [4].

It is obvious that the selective control established in almost all countries of the world does not guarantee the quality of beer in each bottle and does not protect the consumer from counterfeiting. Therefore, for 100% identification of packaged beer products, it is necessary to carry out complete output control at the manufacturer, as well as implement continuous input express control in chain stores and other trade facilities, which is impossible without special methods and tools and their automation.

To achieve this goal, it was necessary to solve the following tasks:

- investigate packaged beer products to create a “standard image” (in terms of density, dynamic and kinematic viscosity, freezing point, viscosity index, similarity criteria, etc.);

- to develop a model of a system for continuous final control at the manufacturer and express control of packaged beer products in chain stores;

- to develop and test a model of a stationary automated complex for quality control of packaged beer products at the manufacturer, built into the automatic bottling line;

- to assemble and test a model of a portable automated complex for express analysis of packaged beer products in chain stores.

Materials and research methods

The analysis of the quality of beer products is carried out according to such indicators as physicochemical, microbiological, organoleptic and safety indicators. However, at present, solutions based on comparative analysis are gaining in popularity, i.e. using the method of comparing the “images” of the standard and the produced product, or / and finding relationships between various parameters, in particular, of packaged beer [5].

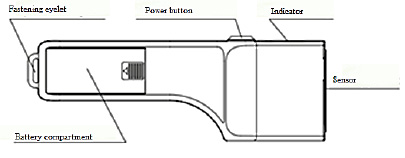

The most interesting, from the point of view of “contactlessness and speed” of identification, is the LQtest 2.8 device (fig. 1), which is designed to test the contents of various closed vessels, such as plastic and glass bottles, cardboard bags and other non-metallic containers [6].

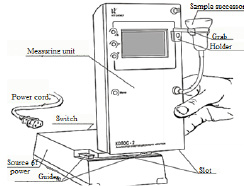

The device allows, without violating the tightness of the vessel, to distinguish such substances as gasoline, incendiary mixtures, acetone, nitroglycerin, nitromethane, various alcohols, ethers and other hazardous liquids from water, soft and alcoholic beverages, dairy products, cosmetics, etc. The device uses the method of quasi-static electric field tomography (fig. 2), which makes it possible to estimate the spatial distribution of the electrical properties of the medium and determine the characteristics of the liquid regardless of the size of the container, the thickness of its walls or the presence of air gaps between the device and the vessel [6].

Potentials are induced on the measuring electrodes of the device, the magnitude of which depends on the voltage source, the distance between the active electrode and the measuring electrodes, and the complex dielectric constant of the medium. In turn, the electrical properties of a liquid (dielectric constant and conductivity) make it possible to unambiguously assess its flammability (table 1).

In this case, the slope of the voltage distribution characteristic on the electrodes 4 (fig. 2) for flammable liquids is always greater than the slope of the voltage distribution characteristic for non-flammable liquids, and the time for examining the container with the liquid is several seconds [6].

Another promising method and a device that implements it is the ULIKOR ultrasonic analyzer of liquid media. The principle of operation of the analyzer is based on the fact that ultrasonic vibrations are passed through the sample and the characteristics of ultrasound are recorded depending on the concentration of substances in liquid media and the temperature of the sample [7].

Fig. 1. General view of the device LQtest 2.8

Fig. 2. Field structure of LQtest 2.8

1 – tested liquid, 2 – vessel wall and air gap, 3 – active electrode, 4 – measuring electrodes, 5 – metal screen, 6 – computing device, V – alternating voltage source, Dn – meters.

It is not excluded that ULIKOR can be implemented in a variant without “sampling”, i.e. for work without opening the container.

However, from the point of view of quality control, these methods and devices do not determine the “amount of product in a container”, and therefore, cannot definitively identify the compliance of a prepackaged beer product with specifications or standards.

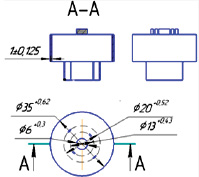

As an alternative to the above methods and devices, a method of weight impedance electrometry (WIEM) with a capacitive sensor-container lid (fig. 4) was developed, which was tested on various packaged liquid products (oil, soft drinks, etc.), where showed sufficient accuracy of their identification by dynamic and kinematic viscosity, electrical conductivity and dielectric constant, freezing temperatures and similarity criteria (table 3) [4,5,8].

Below are the parameters and ranges of their measurements, the permissible limits of the relative error of the measurement results (δ) for Р=0.95 (table 2).

Table 1

Names and parameters of liquids identified by LQtest 2.8

|

Liquid |

Dielectric constant |

Electrical conductivity, cm / m |

|

Water, soft drinks |

81 |

0.01−1 |

|

Ethanol |

25 |

10 |

|

Acetone |

21 |

10 |

|

Nitroglycerin |

19 |

- |

|

Ether |

4.3 |

- |

|

Gasoline, diesel |

2 |

10 |

Fig. 3. External view of the ULIKOR device

Table 2

Names of parameters and measurement errors

|

Indicator |

Range, % |

Limits of relative error, ± δ,% |

Standard deviation of repeatability, σr , % |

Standard deviation of reproducibility, σR , % |

|

Mass fraction of alcohol |

0,1 – 8,0 |

1,0 |

0,24 |

0,5 |

|

Volume fraction of alcohol |

0,1 – 10,5 |

1,0 |

0,24 |

0,5 |

|

Mass fraction of the actual extract |

0,5 – 12,0 |

4,5 |

1,7 |

2,3 |

|

Initial wort extract |

8,0 – 23,0 |

3,0 |

1,7 |

2,2 |

Table 3

Name, dimensions and ranges of parameters of the VIEM method

|

№ |

Parameter name |

Designation |

Dimension |

Range of change |

|

1 |

Product weight |

m |

kg |

0,25 – 3,0 |

|

2 |

Product volume |

V |

m3 |

(0,25 – 3,0) ⋅ 10-3 |

|

3 |

Product density |

ρ |

kg/ m3 |

calculated |

|

4 |

Electrical conductivity |

G |

sm (1/ohm) |

0,000001 – 0,2 |

|

5 |

Resistance |

R |

ohm |

5 – 106 |

|

6 |

Leakage current |

I |

A |

10-6 – 0,2 |

|

7 |

Capacitance sensor |

C |

pF |

10-3 – 1012 |

|

8 |

Temperature |

Т |

ºC |

1 – 50 |

|

9 |

Loss factor |

tgδ |

- |

10-6 – 10-2 |

|

10 |

Specific electrical conductivity |

σ |

μS/cm |

50 – 1500 |

|

11 |

Magnetic permeability |

µ |

H/m |

(8 – 9) ⋅ 106 |

|

12 |

Complex impedance module |

|Z| |

ohm |

900 – 9500 |

|

13 |

Shear angle of complex resistance |

φ |

degree |

minus 180° – plus 180° |

|

14 |

Kinematic viscosity |

ν |

m2/s |

calculated |

|

15 |

Dynamic viscosity |

η |

Н⋅s/m2 |

calculated |

|

16 |

Frequency |

f |

Hz |

10 – 106 |

|

17 |

Dielectric constant |

ε |

F/m |

60 – 90 |

Fig. 4. Capacitive 3-electrode coaxial sensor-cap

The essence of the WIEM method application lies in the fact that, in the case of container closure with a sensor-lid at the beer filling stage, it becomes possible to measure the indicated electrophysical parameters of the liquid, without violating the tightness of the container, and, to determine the “image” of the investigated liquid (table 3), comparing it with the “image of the standard”, thereby identifying the quality and quantity of the packaged product, withdrawing from the sale of counterfeit or expired beer products [5,9,10,11].

Research results and their discussion

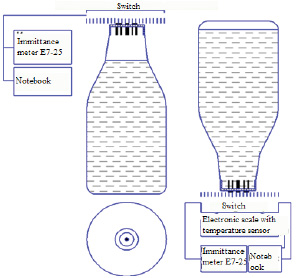

To implement such a comparative express analysis of beer products, a portable automated complex (PAС) was developed (fig. 5).

Fig. 5. Block diagram of measurements using the PAС

It consisted of a laptop, connected to it through the appropriate interfaces of an electronic balance and an E7-25 emittance meter, which through a switching platform connector is connected to a capacitive sensor-cover (measuring the concentration of carbon dioxide vapors), and then installed on the electronic scales “upside down “(By immersing the sensor in beer), and with the help of special software (SSW), the necessary measurements and identification of the beer are carried out within ten seconds. its quality and quantity is determined by comparing the measured and calculated parameters with the parameters of the standards entered / stored in the memory [12,13].

The structural diagram of a stationary automated complex (SAС), built into an automated bottling line for beer products, differs from the PAС (fig. 5) by the use of an industrial computer and an E7-29 emittance meter, which make it possible to more accurately form a “beer product image” from the manufacturer [9,14].

Conclusion

Thus, the model of a continuous automated control system for beer products can be represented as a combination of the following subsystems:

– subsystem of consumers – beer traders, consisting of a portable automated complex (PAC);

– subsystems of beer producers that have applied sensor caps, SAС and placed “electronic certificates” on their website on the Internet – “images of standards” of the beer produced, which can be uploaded to PAС;

– subsystems of municipal supervision over the quality of liquid packaged products, in particular beer, through periodic inspections by supervisory authorities of chain stores and other trade objects using PAС.