The concept of technological system, whose structure supposes certain elements of technical-technological support, is not specified in regard to beer lifecycle. General comprehension of the concept is accepted in regulatory documentation. According to GOST R 57194.1-2016, technological system is understood as «cohesive integrity of a limited number of interconnected material objects, which has subsequently interacting sensory and executive functional parts with a model of their presupposed performance in the space of equal stable states and which is able to perform required by design consumer-oriented functions independently under normal conditions, being in at least one of the target states» [1, p. 2]. In the abovementioned regulatory documentation technical system (providing technological process in context) is described as «networking hierarchy of verified mechanisms, which provides implementation of technological process». At the same time, in GOST R 57194.1-2016 it is underlined that «during various stages of life cycle those mechanisms can be presented by documentation, software, processing equipment and others». It is known that development and production of any food substance or drink suggest structuration and (or) creation of elements of technical-technological support. However, the term «technical-technological support» itself is non-standardized, even if in manufacturing practices it is usually understood as «a kind of activity, aimed at implementing complex technical and technological tasks, providing integrated functioning of machinery and technology». Regulatory documentation states the term «technical-technological support of manufacturing» and limits it to be a kind of production activity of an enterprise or a group of enterprises, which provides technological readiness of manufacturing to produce goods that are capable of satisfying the demands of the client or the market of the given type of goods (GOST R 50995.3.1-96. Technological support for the creation of products. Technological preparation of production). It must be noted that elaboration of technical-technological support with regard to stages of life cycle of beer with preset properties requires systemic and process approaches, while systemic approach must be targeted to provide functioning of machinery (equipment and measuring means) and to create technology as a cohesive system, and process approach is to be aimed at monitoring the progress of the product toward predetermined requirements.

Purpose of the study is to prove the necessity and specifications of the systematization and development of the elements of technical-technological support in beer quality management with preset qualities with consideration of beer lifecycle.

Material and research methods

Analysis and problem statement are carried out on the grounds of systemic approach; the methods of directed and arranged research were used, as well as methods of problematic and thematic analysis. Generalizations and conclusions were received on the basis of systematic analysis by means of applying the HACCP principles and quality management tools.

Table 1

Main elements of technical-technological support of beer quality during various stages of product lifecycle

|

Lifecycle stage |

Elements of technical-technological support |

|

Marketing and market surveillance |

Methods of consumer preferences evaluation, online-resources, software |

|

Project planning and development of beer with preset qualities |

Technological processes (malting; wort production; wort fermenting; beer storing; filtration and dispensing) |

|

Inventory and logistics management |

Fermentation tanks, wort kettles |

|

Production (technological process of brewing) |

Software, qualified staff, professional discipline |

|

Monitoring of raw product, semi-product and final product |

Adequate expertise, machinery maintenance, instrumental analysis of raw product, semi-product and final product. |

|

Packing and storing beer and beer drinks |

Labels with information about functionality of beer and flavouring profile of beer |

|

Offtake of beer |

Wholesale trade (wholesale chains of stores and storehouses), retail trade (chains of specialized retail stores and department stores) |

Research findings and discussion

Legal ambiguity in distributing responsibilities for quality and safety of the manufactured products and provided services among the State and legal bodies was characteristic for the transitioning period of introducing the Federal Law «On Technical Regulation» (2002-2012). As it was previously stated in the monograph by one of the authors of this article, «As of today, according to the Federal Law «On Technical Regulation» the manufacturer is responsible for everything that may affect the quality of end product» [2, p. 419]. It became possible to legally fix the «Fields of responsibility» due to presently created system, called Technical Regulation of Customs Union 021-2011, which is a list of documents on standardization, ensuring adequacy to the requirements of this Technical Regulation. However, these changes did not affect the area of beer manufacturing. At this point, there is no accepted Technical Regulation for alcoholic products, to which beer and beer drinks belong since 2011. Technical regulation of the Eurasian Economic Union TR EAEU 047/2018 on «Safety of alcoholic products» will not come into effect earlier than 9.01.2021.

The necessity to arrange the elements of technical-technological quality support into a system is connected with the peculiarities of biotechnological stages of brewery. Having analyzed modern tendencies in brewing technologies [3, 4, 5], we discovered that beer quality can be affected by various factors, from the quality of basic raw material up to following the rules of storing final product. With the aim to justify the elements of technical-technological support capable to affect beer quality, they were systemized with consideration to main stages of manufacturing life cycle (table 1). Product life cycle is understood as «a whole of interconnected processes of product state transition in the course of its creation, usage (running) and post-consumer recycling (with disposal of wastes by means of utilization or discharge)» (GOST R 53791-2010) [6, p. 6].

Package of preset consumptive beer qualities, determined by biological value and lowered toxicity is scientifically proven in specialized published research by one of the authors of this article [3].

On the stage of marketing and market surveillance it is essential to use methods of consumer preferences evaluation. Aside that we recommend [2] to apply methods of qualitative analysis (visual method, interview, organoleptical analysis, testing) and quantitative methods (spread index, scoring method, point rating method).

Analyzing the specifics of brewing technology, we relied on the HACCP principles (Hazard Analysis and Critical Control Point). In the framework of the research carried out on the department of Metrology, Standardization and Certification of Orenburg State University, the chosen approach allowed to establish critical points of brewing technological process that require monitoring as well as to suggest model production engineering measures for eliminating discovered discrepancies (table 2). It must be noted that a vast majority of correcting actions like adding certain concentrations of ingredients, or, alternatively, lowering the concentrations of unrepresentative substances (dilution), can be performed by automatable dispensing technical devices for liquids or powder products. Similar technical solutions are presented in proprietary designs of the department of Metrology, Standardization and Certification of Orenburg State University (patents of the Russian Federation 2423417 [7] and 2383587 [8]). At that, technical devices with influence on the main process, like measuring temperature of internal environment in particular, possess well-arranged system of automated regulation with feedback, along with sufficient resource of power. It is to be underlined that technical solutions designed within the department of Metrology, Standardization and Certification of Orenburg State University help to solve the problem of automatic performance in technological process of manufacturing beer with preset qualities. A technique of managing the process of brewing is elaborated (patent of the Russian Federation 2396101).

We have considered a well-known fact [9] that maintaining a technical system (as a part of successful solution to the problem of providing reliability) must be determined by the state of computing machinery, experimental and production facilities, as well as the level of technology and metrology.

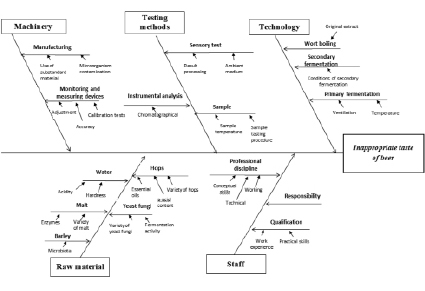

In the framework of systemic approach, to elicit the factors determining the taste of beer, we applied one of the quality management tools – the Ishikawa diagram, which made it possible to discover key interconnections between various factors, and so to understand the investigated process better. It is known [10] that in quality management Ishikawa diagram helps to determine the main factors with the most significant influence on the development of the studied problem. Problem analysis based on Ishikawa diagram is aimed at preventing or eliminating the effect of those factors. Considering beer quality, we have studied the problem of inappropriate taste of final product (picture).

Reasons for inappropriate beer taste can be distributed into 5 key categories: raw material, equipment, technology, monitoring procedures and staff (picture).

Table 2

Suggested correcting measures to improve quality of beer with preset properties

|

Main stages of beer manufacturing |

Measures for quality control |

Correcting measures |

|

1. Incoming quality control of raw material |

Reliable measures providing quality of grain raw material are absent |

Micronization of grain raw material, periodical ozonizing (on long-term storage) |

|

2. Water conditioning |

Water quality control (for mashing and boiling of wort) |

Electrochemical cleaning |

|

3. Mash filtration and wort preparation |

Providing complete extraction of grains; adequacy of total density of original extract |

Cleaning the pore spaces clogged with grains; Recovering trouble wort from decanter to mash tub |

|

4. Wort boiling |

Preventing accumulation of psychedelic and toxic components; Automated control of density, volume, temperature, sugar content |

Sugar sufficiency control; Technological additives for model wort content correction; Applying additives to wort content |

|

5. Main fermentation |

Temperature control; Proportion of nitrogen and carbon in nutritive medium; Test of wort density, sugar and ethanol concentration |

Portioned adding of sugar syrups |

|

6. Pre-final filtration and dispensing |

Adding harm reducing substances to beer; Signals of model unacceptable deviations in monitored parameters |

Supplemental adding of components that compensate for qualitative deviations in semi-product; Adding enzymes, sugars, lactic acid, phosphoric acid or acorbic acid |

|

7. Instrumental control of ogranoleptic beer qualities |

Premarket laboratory testing of finished beer quality |

Justification for the limits of discovering flavor carrying substances (in regard to existing data); Instrumental measuring of concentrations of main flavor carrying substances; Flavour dose calculation for i-substance; Total flavour dose calculation for beer sample |

Model Ishikawa diagram for establishing the main reasons to the problem «Inappropriate beer taste»

Conclusion

Elements of technical-technological support in beer manufacturing are supposed to be regarded as factors that ensure preset consumer properties of final product. Their analysis, systematization and structure choice must be performed with consideration to the peculiarities of the finished drink lifecycle stages and the technical level of manufacturing. At the same time special emphasis must be put to development of regulatory documents, as well as quality monitoring for raw material, semi-product and finished beer.

The Ishikawa diagram made it possible to discover 5 main reasons for low quality and competitive ability of beer:

– Inappropriate quality of raw material, and primarily, variety of yeast fungi. Substantial effect is made by the methods of enhancing the properties of barley and malt, along with varieties of hops and water;

– Troubled technological scheme of production provokes defects in flavor, which significantly lowers the competitive ability of finished drink;

– Manufacturing equipment must be chosen with consideration of modern requirements;

– The influence of staff providing technological and measuring instrumentation has a subjective nature. However, professional level of training, qualification and professional discipline must be taken into account as well.