Here we develop and implement automation and control system for the process described above.

Shipment of liquid petroleum products is a dangerous process, because of following factors:

– petroleum products, in particular gasoline, is a flammable explosive volatile substance which exerts a general toxic and narcotic effect that can become a cause of death;

– increased vibration of moving machines and mechanisms;

– excessive pump noise;

– the threat of electric shock [1].

The introduction of an automation system for shipment of liquid petroleum products is necessary for solving the following tasks:

– increase the safety of the process;

– reduce the total cost of the process;

– provide an ability of the remote process control;

– reduce the impact of human labor on the process;

– counteraction and diagnostics of emergency situation .

Automated process of shipment of liquid petroleum products from the discharge railway trestle consists of the next stages:

– pumping gasoline from a rail tank to a storage tank;

– storage of gasoline for future use;

– pumping gasoline for catalytic reformer.

Now we take a closer look at all stages of the automated process of shipment of liquid petroleum products from the discharge railway trestle.

Stage 1.

The installation of pipe communications is carried out through which, with the help of a powerful pump, gasoline is transported from the railway tank to storage. There are also spare pipe communications with a separate, emergency, pump. At this stage, the automation system controls the valves, continuously measuring the inlet and outlet pressure of the pump, the temperature of gasoline.

Stage 2.

Gasoline is stored in a storage barrel, where the level and temperature are constantly measuring.

Stage 3.

With the help of pumps gasoline is transported to the stage of catalytic reforming on pipe communications. There are also spare pipe communications with a separate, emergency, pump. At this stage, the automation system also controls the valves, continuously measuring the inlet and outlet pressure of the pump, the temperature of gasoline.

Initially, it is necessary to select the appropriate level of automation. The choice of local automation is not optimal, because such a system is characterized by low reliability and poor scalability. Based on this, the choice falls on the use of process automation at the level of APCS [3]. It uses microprocessor technology, which have some advantages:

– full automation of the process of interaction with information;

– formation of archives and reports;

– ability to communicate with staff;

– monitoring of devices, their operation and condition.

The main purpose of using process control systems for the process of shipment of liquid petroleum products – diagnosis and prevention of accidents.

The automation system, for the implementation of the goals, should perform the following functions:

– collection and primary processing of information;

– control of technological parameters, namely:

– automatic measurement of the flammability limit and activation of the alarm when that value is exceeded;

– registration of pressure at the pump inputs and discharge lines, activation of the alarm in case of deviation from the nominal values.

To perform such a range of functions in the designed automation system, it is advisable to use computer technology that means automation at the level of APCS is necessary [2].

Due to the large territorial distribution of controls and the presence of a large number of input-output signals, we decided to use a centralized control system. The main advantages of this system are:

– ensuring high coherence among the elements of the organization;

– improvement of control over the work of production departments;

– process controls by hands of those who are more aware of the general situation in the system;

– elimination of unnecessary duplicate control functions.

But, of course, that automation system has its own disadvantages, such as:

– it is necessary to spend a relatively large amount of time on the movement of information, that means that the possibility of loss or distortion of the information increases;

– the most important decisions are made by those who do not specialize in a particular situation.

The automated process control system consists of the following levels:

Lower level of automation.

This level includes sensors, measuring devices and actuators. It collects information about the parameters of the process, the state of the equipment and the implementation of control actions.

Criteria for selection of devices:

– ability to perform tasks;

– reliability of structural design and its compliance with the category of fire and explosion hazard of the process;

– high metrological characteristics.

Based on these criteria, we selected following devices:

– measurement of hydrocarbon vapor concentration in a mixture with air: stationary sensor – gas analyzer DGS ERIS – 230-IR;

– tank liquid (petrol) level measurement: non-contact radar level transmitter – Micropilot FMR 60;

– pressure measurement on pump discharge lines: absolute pressure transducer EJA510A;

– measurement of pressure at the inputs of pumps: absolute pressure transmitter EJA510A;

– shut-off valve for electric motor: stainless steel wedge gate valve with sliding spindle;

– electric motor for shut-off valves: IQ Pro multi-turn electric drive;

– spark protection barriers: Analog – BREEZE 420P-Ex, Discrete – BREEZE NAM-Ex.

Medium level of automation.

At this level, we provide automatic control and regulation of process parameters, start and stop of equipment, emergency response. The middle level is represented by a programmable logic controller (PLC).

PLC selection criteria steel:

– high MTBF;

– reliability of structural design and its compliance with the category of fire and explosion hazard of the installation;

– relatively inexpensive.

Based on these criteria, we selected the FCN-RTU controller which belongs to the STARDOM system controller line [4].

The advantages of the controller described above:

– wide operating temperature range (-40...+70C) and mounting height range (up to 3000 m);

– wide operating voltage range (10...30 VDC. input current);

– low heat dissipation, no need for active cooling;

– CPU self-diagnosis, temperature control, and other;

– support for hot-swapping additional modules (except CPU).

The FCN-RTU controller includes:

– base module NFBU050;

– power module NFPW426;

– the CPU module NFCP050;

– selectable input module NFDV151;

– discrete output module NFDV561;

– analog input module NFAI143.

High level of automation.

At this level, the APCS are able to visualize the system and the manager or operator can interact with it. First of all, the equipment of this level and the software performs the following functions: collection, processing, storage and delivery of information, depending on the requirements of the operator.

In addition, the system provides not only interaction with information relating to the parameters of the process and the operation of automatic safety, but also external interference of staff in the process.

Structure of the Standalone concept

With the help of software, we have an opportunity of a remote control of process and adjustment of parameters of SU is carried out.

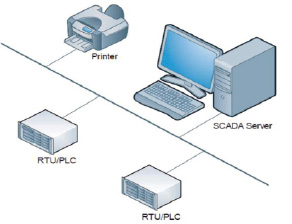

In our case, the high level of the APCS is represented by the operator station (OS), implemented in the form of a personal computer (PC). OS connected to the controller by an Ethernet network.

Software.

For communicating with the controller FCN-RTU we used the system platform for real-time applications SCADA FAST/TOOLS (Flexible Advances Techniques System Tools/ System Flexible Advanced Techniques / Tools). It includes a web-based supervisory control interface, OPC client-server functions, data collection from numerous controllers and devices, alarm management and data archiving.

Type of communication:

– Ethernet;

– optical fiber;

– radio;

– wireless.

At the moment, there is a large number of possible configurations of the fast/TOOLS system for the implementation of work on a separate technological process, and on a huge, significantly geographically distributed production. In the presented project, it would be enough to use the simplest configuration, called Standalone, where the runtime and development environment is on one machine (full-featured SCADA) [5].

The structure of the Standalone concept is shown in figure.

In the end, we made an economic calculation of the cost of implementing the automation system in the process of gasoline shipment. It showed that the use of such a system is beneficial for implementation.