Prevention of coal ignition in sailings of mining enterprises has obtained a special significance in terms of strict requirements towards ecological condition of natural environment [1]. The most efficient method of avoiding fires is implementation of mining technologies that imply preventive measures against coal ignition.

The object of this research is prospecting area of a cut that carries out coal mining in conditions of sharply continental climate, defined by significant oscillation of temperature, cold and continuous winter and short, but hot summer. Snow surface preserves during five to six months. The prevailing direction of wind – West and South-West with average speed of 4,4 m/s. These aspects are considered while locating external sailings of mining enterprise and construction of dwellings [2].

The coal is presented by layers that are located in parallel at different depths and characterized by a complicated composition and low solidity. Moist content varies from 1,03 to 2,1 %, actual solidity equals 1,47 t/m3, coefficient of solidity equals 0,6-2,33, and angles of fallout – 5-80°. Quick oxidation and further ignition is typical for coal. Metane content grows along with depth of layer location and varies from 3-3,5 m3/t to 7,5-8,2 m3/t [2].

Uncovering and storing rocks are presented by clays, clay loam, sandstone, argillites, and aleurolites [2].

Technology of mining at a site implies facilitation of one internal and two external sailings. Transportation of uncovering rock is carried out by trucks, and their pushing and planning of sailing surface in the area of unloading – by bulldozers.

In order to improve stability of external sailing board during formation of lower level that falls down along thalweg of ravine, it is necessary to implement technological scheme of sailing formation that implies directing front of mining operations. This front must be located in perpendicular to axis of ravine thalweg, and dumping must go along its direction.

Front of dumping works is divided into three sectors. First of all, dump goes along water divisions and ravine slopes – lateral areas, characterized by lower altitude. The central area, located along ravine thalweg and defined by the greatest altitude, is dumped last. The central area of sailing is dumped with more solid rocks (sandstone, argillites, and aleurolites), and laters areas – with less solid types (clays and clay loam). No more than two sites can operate, the third site is reserved for stabilization of the emerging tension.

Formation of sailing along ravine thalweg is carried out with preliminary dump of leading embankment that is located at the same axis as the lover border of sailing. At the same time stability of the lower level in the formed sailing is regulated by height and depth of the leading embankment. Width of the leading embankment is defined via method of its construction and parameters of the aggregate that forms dumping, leading degree is defined according to width of foundation riser prism that, in its turn, is defined according to power of the weak layer. Maximum height of external sailing levels must not exceed 20 m.

Table 1

Characteristics of measures on preventing coal ignition

|

Parameter |

Units |

Value |

|

Fire-safe thickness of non-isolated layer of sailing rock mass that contains coal |

m |

0,75 |

|

Degree of densifying coal-containing sailing rock mass that secures fire safety of sailing |

– |

0,7 |

|

Thickness of the isolating cover, composed of inert rock |

m |

0,35 |

Table 2

Set of equipment, required to reveal ignition centers

|

Measurement tool |

Range of evaluated temperature, °C |

Standard error, ± °C |

Purpose |

|

Thermal camera |

from 20-40 to 1500-2000 |

0,1 |

Measuring temperature according to thermal radiation |

|

Pyrometer |

from 20-30 to 900-1200 |

2 % |

Contactless temperature measurement |

|

Thermometer |

from 0-600 to 30-30000 |

0,5-1,0 |

Thermometer with protective box for contact temperature measurement |

|

Thermal-electrical transformer |

from -40 to 1000 |

0,15-0,5 % |

Measurement and indication of temperature in complete set with thermal pairs |

In order to prevent spread of open fire centers around stocks of broken coal and coal dust isolation of layers, operation sites, and the prospected area with inert rock is implemented. Thickness of the inert layer, composed of clay and clay loam equals 0,35m and is a subject of densification. Laying of rock mass that contains coal, into sailing is carried out in layers around the whole area of storage. Rock mass, carrying coal is planned with bulldozers with formation of layers 0,75 m thick. Along with laying each layer is densified with trucks up to degree of 0,7 and moisturized with water (table 1).

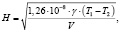

Fire-safe thickness of non-isolated layer of sailing mass H is defined according to formula [3]:

(1)

(1)

while γ is thermal conduction of sailing mass; T1 is critical temperature of sailing mass heat; T2 is average temperature of the warmest month of the year; V is speed of oxygen sorption in sailing mass.

Degree of sailing mass densification that secures fire safety of sailing e is defined according to the formula [4]:

(2)

(2)

while k1 is coefficient of sailing mass air permeability; d is equivalent diameter of sailing mass pieces.

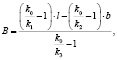

Thickness of the isolating cover B is defined according to the formula [4]:

(3)

(3)

while

(4)

(4)

while k0 is coefficient of air permeability in sailing mass in the area of heat; k2 is coefficient of air permeability in densified sailing mass; k3 is coefficient of air permeability in isolating material; l is width of heating area in sailing mass; b is thickness of densified sailing mass layer.

Significant advantage in revelation of fire centers among rock sailings at early stages of ignition can be achieved with instrumental control of their thermal condition. Early signs of coal-bearing rock heating as well as opportune measures of preventing fire spread are rarely taken according to the results of visual observation. Possibilities of observing rock sailing areas with revelation of ignition centers and burning areas are provided by equipment, described in table 2 [5].

Temperature filming must take place on regular basis at current not-burning as well as burning not operational sailings several times a year – in spring and autumn. At sailing territories, temperature of which exceeds temperature of other mining sited by more than 5 °C or value of 45 °C, measures of its decrease must be taken [5].

Conclusion

1. In order to improve board stability it is necessary to implement technology of forming external sailings that implies change in mining operation front and dump of leading embarkment.

2. Prevention of coal ignition in external sailings requires isolation of layers, operation sites, and the prospected area with inert rock.

3. Technology of forming external sailings with leading embarkment and measures of ignition prevention must include formation of underlying layer from inert rock, planned with bulldozers and densified with trucks; further placement and planning of coal-bearing rock with bulldozers truck densification and moisturizing with water; formation of covering layer from inert rock with bulldozers in collaboration with trucks, etc.

4. Practice of heat control over rock sailings must include instrumental means of locating coal ignition threats, as visual observation often provides insufficient or unreliable information on source and area of fire.

The work is submitted to the International Scientific Conference “New technologies, innovation, invention”, Israel (tel Aviv), 29 April to 6 may 2017, came to the editorial office оn 21.02.2017.