Computer modeling and advanced furnace processing technology in electric steelmaking

Using methods vakuumno¬go refining, in essence, it is a necessary condition for improving the quality of steel produced a number of brands. In particular, treatment of steel in the vacuum degassing has become a major, a mandatory part of the process of smelting pro¬tsessa bearing, electrical, avtolistovoy steels. Vacuum casting process ensures high quality on-duty metal casters, quality improvement clyabov and billets and the reduction of their rejection by the macrostructure and surface defects, increased productivity steelmaking units, a decrease in volume and utilization of equipment for termoob¬rabotki, reduced consumption of ferro-alloys and deoxidizing agents, elimination of the marriage on the chemical composition and reducing the anisotropy of mechanical properties of finished steel, a minimum spread of rolled metal properties from heat to heat.

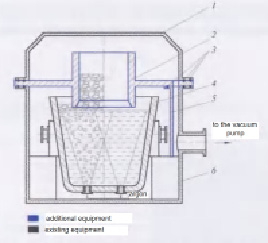

When the metal in the ladle vacuum treatment ladle is placed in a sealed chamber from which the steam jet pump is evacuated to a residual pressure of 0.133 kPa. By reducing the pressure of non-deoxidized metal boils to form CO. Due mixed metal boil, thereby equalizing the temperature and chemical composition, as well as the removal of hydrogen, nitrogen and nonmetallic inclusions. The chamber for vacuum processing of a steel housing with a sealed lid, with hoppers materials. Inside the casing and cover futeru¬yut refractory materials. To create a vacuum above the metal (vacuum) used steam jet pumps and a capacity of 400 kg / h of dry air.

The treatment is carried out in a vacuum casting ladle slide with 500 ... 700 mm headroom height with basic or high-alumina lining heated before the release of melting up to 1100 ... 1200 °C. Evacuation accompanied by AK Steel kipeni¬em weak and poor metal stirring, so buckets equipped with means for blowing argon melt. Several designs predus¬matrivayut ladle on the platform, and cover them with lids vacuum-wire equipment for dispensing kont¬rolno materials and instrumentation.

Analysis of the data in our possession shows that the major structural defect ladle degasser is a problem with the value of “free board” ladle.

For example, in [7] shows the effect of the size of the reaction zone workspace chipboard intensity Purge al. Process parameters on the formation of splashes and splashing furnace walls. It is shown that the resulting empirical relationships can be used to study mechanisms of spraying in actual steel assemblies, including, for secondary treatment and corrected for the elements of similarity theory.

To eliminate overflow and splashes across the board in the ladle furnace treatment is necessary to increase the height of free board ladle to 1200-1300 mm, which can handle only melting at 10-15 % less weight than the standard bucket seats. This problem is especially acute for metallurgical plants built earlier, where the conduct of the vacuum refining technology was not provided in the steel ladle, and hoisting machines and metal structures are designed for standard bucket mass, ensuring safe transportation. In the case of use in such production technology vacuum VD or VOD has to produce melting of reduced weight, which leads to a decrease in productivity and increase in cost of production. In the construction of new production, providing application or VOD VD installations for use in steelmaking unit capabilities full bucket falls significantly increase the size and accordingly all the mechanisms and the whole building, which leads to a significant increase in capital costs. In this connection, vacuum is provided a method of refining steel in a ladle, tube and device for its implementation [8]. Schematic diagram of the vacuum process began with the new development is shown in Fig. 1.

To solve the problem of magnitude reduction freeboard applied fundamentally new approach, which uses the separation chamber vacuum space into two zones with different vacuum. At the same time, extension, which rests on the flange vacuum chamber with the necessary gaps with respect to the end and side of the bucket, made with the lined pipe. The length of the nozzle is selected so that during the vacuum treatment with a lower end immersed in the slag-metal emulsion rising to a certain depth, thereby dividing the inner space of the chamber into two zones with different degrees of dilution, the extension is in the vacuum zone is higher than under it. When lifting the slag-metal emulsion no overflow across the board is provided as a result of the hydraulic shutter effect when lifting the boil and slag-metal emulsion occur mostly inside the nozzle, the volume of which is selected based on the conditions of guaranteed exclusion of its overflow through the upper end of the pipe. Thus the rise of metal and slag in the ladle the area between the pipe flange and is practically absent.

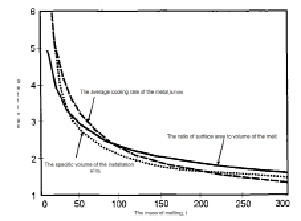

It is found that after evacuating and lifting height of the metal with the slag outside the nozzle does not exceed 100–150 mm against 700 ... 1000 mm from the inner pipe adapter. This demonstrates that the process of boiling and heavy metal during vacuum degassing occurs in the nozzle, therefore the height of freeboard ladle can be greatly reduced. Comparison evacuation systems from the standpoint of economic efficiency types of [9] leads to the conclusion that the capacity ladles at 10-300 m depth ratio of metal to the ladle diameter (H / D), equal to 1: 1, the ratio of surface area to volume (S / V) is reduced from 8 to 1,5.Kak consequence empirical average temperature drop rate of alloys in ladles of small capacity is more than 6 dg / min in large ladles reaches 1.2 dg / min. conclusion can be drawn from this that the problem of reducing the magnitude of the free board becomes particularly important when processing small batches of mass in the case of relatively large installation volume resistivity (Fig. 2).

Computer modeling allows you to explore the features of the design of metallurgical equipment at the stage of development and design, which reduces the likelihood of errors at the manufacturing stage.

Fig. 1. The concept VODF process [8]: 1 heat shielding cover; 2 – extension; 3 – seal; 4 – casting ladle; 5 – insertion; 6 – vacuum chamber

Fig. 2. Effect of weight of steel in ladle on the technological parameters of vacuum

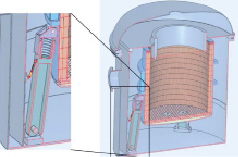

Fig. 3. Modl vacuum chamber for VODF process

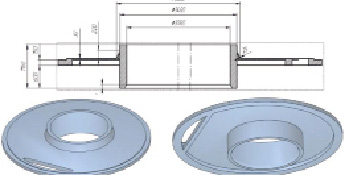

Fig. 4. provided by the present structure of the spacer

The CAD “3D Compass” we have created a vacuum vessel model and a spacer designed to satisfy discussed above. In this construction, the outer bearing ring and are connected by a membrane tube made of a steel plate and reinforced ribs. Finite analysis of the structure showed that when exposed to a temperature in the spacer will arise voltage, the value of which exceeds the strength of the metal. Dangerous sections are air channel edges, attaching the membrane to the stiffeners and pipe attachment points to the membrane.

There are also significant thermal deformation of the membrane, the nature of which is shown in Fig. 3.

We have proposed a spacer structure shown in Fig. 4. Rejecting the ribs, we propose to strengthen the place of critical stresses. Airway aperture reinforced bottom beam, which also serves as an additional seal in sealing degasser and fixing membrane reinforced discharge nozzle ring.

Finite analysis shows (Fig. 3) that under equal other conditions the voltage of the proposed structure of the spacer is smaller and distributed more evenly over the volume. Furthermore, in the present embodiment, thermal deformation is significantly reduced, and above all – are completely absent in the air passage area. Mass of the proposed construction of 37 tons, 5 tons less than the base.

As part of the educational work, contact was also modeled the vacuum chamber (Fig. 6) for VODF-process, a feature of which is that it can take buckets of different diameters due to variable geometry bearing struts. The maximum design load on the strut of a total of 500 tons, and chamber dimensions are designed to accept standard bucket capacity of 100-300 tons. This design of the vacuum chamber is more versatile and allows to easily move to another vessel buckets.

Application considered degasser design allows not only to intensify the process of vacuum metal, but also increase the melting mass of 10–15 tons by reducing the height of the free board. In addition, the ability to install different sizes of buckets increases the versatility of the machine, it can be used without adjustment for different working conditions.

Conclusions

The design of the installation of modern vacuum degassing ladle, which provides a standard weight of steel in ladle by reducing the amount of “free board”. It is shown that the average weight of each melt processed on a degasser for molten steel VDF / VODF technologies can be increased by about 15 % compared with traditional VD / VOD technologies, thus decreasing the thermal load increases and resistance ladles; due to a more powerful mixing of the molten metal with slag reduces the time required processing cycle began, improved metallurgical characteristics of the final product and reduced energy consumption.