When choosing the materials in the package of the product there are problems of meeting customer requirements with high quality competitive clothing. The rapid development of textile materials with new consumer properties, as well as the fierce competition of products in the garment factories are forcing manufacturers to search for new design solutions range, but also use the replacement materials for the visual diversity of products.

Expansion of the range and its visual diversity provides the enterprise with a high level of product sales and consumers – with a feeling of satisfaction of their social needs. Expansion of the range and its visual diversity provides the enterprise with a high level of product sales and consumers – with a feeling of satisfaction of their social needs.

There are more than 20 consumer properties of materials such as shrinkage after treatment and washing, color fastness of materials, threads spread in the fabric and seams, pilling, elasticity, crease-resistance, cutting of needle, drapability, tensile strength, extensibility, hygroscopicity, breathability, water resistance, color stability of materials, resistance to abrasion, ablator characteristics and others.

Various authors and research teams have developed methods to assess different properties. Most of the methods require special expensive equipment, which enterprises producing garments do not have.

Sewing enterprises, within existing funds, can test materials on the defects of fabric using visual characteristics; measure the shrinkage after the wet-heat treatment and duplication; check threads spread in the seams and material cutting with the help of pre-sew seams and stitches, organoleptically assess the bonding capacity of the main fabric with fusible interlining material – its adhesion.

It is obvious that these indicators are not enough to manufacture the product meeting all requirements of consumers. While selecting the package to ensure high product quality it is necessary to consider the properties of all materials, making it. Clothes, basically, are a multilayer system consisting of: main material, lining, fusible interlining materials, insulation, thread, glue and accessories. The properties of each component of the package are important for the production of high quality products. Tests of one parameter are not sufficient to determine the compliance of a package of materials to the specified requirements to the product, a set of properties that are included in its package are more significant.

Evaluation methods of properties of materials are aimed at studying the properties of the tested material. The specificity of the production of garments requires knowledge about the interaction of package materials in various units of the design, especially in products used in extreme conditions. Unit of garments is a complex system, testing of which is much more complicated than testing of individual materials.

Unit design in this work is considered as its structure, consisting of parts: materials included in its package, and methods of joining parts. The strength of the garment largely depends on its cut and shape, properties of materials included in the package, quality of workmanship and operating conditions.

It was found out that one of the affected units in clothing for various purposes, is the design functional and decorative unit “pocket”. Characteristics of a construction site “pocket” are laid on stages: confectioning of materials, when choosing a method of processing a pocket, and the choice of regimes of the wet-heat treatment and pressing.

The stability of the structure unit “pocket” is provided by a set of operations: the packaging of each component of the packet unit, where each component of the package plays a role in the future operation. The packaging materials of the construction site “pocket” with desired resistance properties has a high operational value.

In the enterprise, replacing one material for another, the confectioner primarily focuses on information about the fibrous structure of the material presented in the passport of the piece. Fabrics of one destination having the same fibrous structure have different consumer characteristics, so manufacturing garments entails problems of confectioning materials for the same range.

To identify the set of properties affecting the stability of the structure unit «pocket» 13 articles of fabric used for making jackets, coats and suits were selected. The materials having the same fiber composition were chosen in each group. It was done in order to experimentally establish the degree of influence of the surface density and thickness on consumer properties of clothing. The investigated materials are presented in Table.

Tissue samples

|

Group |

Sample |

The fiber composition |

Product group |

Surface density g/m2 |

Thickness, mm, under a pressure of 0,2 kPa |

Appearance |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

|

№ 1 |

1 |

100 % polyester |

Jackets fabric |

82,3 |

0,12 |

|

|

2 |

100 % polyester |

199,1 |

0,32 |

|

||

|

3 |

100 % polyester |

57,1 |

0,09 |

|

||

|

№ 2 |

4 |

70 % wool; 30 % polyamide |

Coat fabrics |

428,1 |

2,32 |

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

|

№ 2 |

7 |

70 % wool; 30 % polyamide |

Coat fabrics |

399,5 |

2,12 |

|

|

№ 3 |

5 |

65 % polyester; 31 % viscose; 4 % elastane |

Suit fabrics |

410,0 |

1,2 |

|

|

6 |

65 % polyester; 31 % viscose; 4 % elastane |

372,9 |

0,98 |

|

||

|

№ 4 |

8 |

43 % wool; 53 % polyester; 4 % lycra |

Suit fabrics |

241,4 |

0,72 |

|

|

13 |

43 % wool; 53 % polyester; 4 % lycra |

191,9 |

0,38 |

|

||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

|

№ 5 |

9 |

62 % polyester; 34 % viscose; 4 % elastane |

Suit fabrics |

375,5 |

1,18 |

|

|

10 |

62 % polyester; 34 % viscose; 4 % elastane |

236,2 |

0,56 |

|

||

|

№ 6 |

11 |

73 % polyester; 22 % viscose; 5 % elastane |

Suit fabrics |

217,4 |

0,44 |

|

|

12 |

73 % polyester; 22 % viscose; 5 % elastane |

302,1 |

0,56 |

|

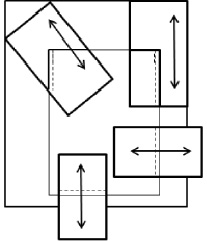

For the first phase of testing materials the samples of units patch pockets lined without the use of interlining materials for the main fabric (single layer clothing) were manufactured. The aim of this phase was to identify problem areas of the site during the operation. The task was to study its mechanical properties at break. That is why the methodology of site garments research, based on the the vectors of load application on a unit was developed (Figure).

The pocket was divided into 3 zones: the seam at the bottom of the pocket; the seam in the side part of the pocket; and the seam in the corner part at the top of the pocket. The method of load application was used along the lines of the base fabric (the seam at the bottom of the pocket); along the line of the weft of the fabric (the seam in the side of the pocket, the seam in the corner part at the top of the pocket);under 45°(the seam in the corner part at the top of the pocket).To study the mechanical properties of the units, the samples were spread in a uniaxial direction with the use of semicycle characteristics. The samples of pockets were subjected to a relatively rapid stretching, bringing them to destruction.

Vector load is applied to the unit “pocket”

Analysis of the values of the breaking load of joints of materials of the same fiber composition in one product group at different surface density has shown that there is no regularity in the results of the strength characteristics.

Based on the results of testing groups of samples of the unit «pocket», it is concluded that not only the thickness and surface density of materials included in the package unit, influence the explosive characteristics of the materials, but weaving, impregnation, and fabric treatment.

After the first experiment there appeared a question about the universality of recommendations to ensure the stability of construction nodes of apparel products at the stage of confectioning materials in the package of the product. The stability of the structure depends not only on material characteristics included in it, but also depends on technological processing methods. In the second experiment, observing the same technical terms, two methods of strengthening the construction site were applied: technological horizontal tack perpendicular to the seam felling pocket) and confectioning (different types of fusible interlining materials). Using the vector method of load application it was possible to determine that the effect on unit strength has a combination of factors: physical and mechanical properties of the core material and thread, cloth piercing with a needle (needle diameter), cutting the interlining strips, the wet-heat treatment regime and duplication.

On the basis of experimental data the method of assessing the sustainability of the construction site pocket to external influences was developed and the factors influencing the process of confectioning the package of materials for the construction site “pocket” were defined.

Obtained data can be used to predict the stability of the structure during operation, but it is only one of the indicators of quality. To conduct a comprehensive evaluation of the various units of garments material resources and special equipment is required that is fabric-consuming.

To improve the quality of products we can test garment units and packages of materials on the basis of independent specialized laboratory source of funds. Constant updating of assortment of garments and the appearance of new types of textile materials require the development of scientifically – based methodology of engineering confectioning of materials.

The use of new textile materials is impossible without scientific methods of confectioning without examining their impact on human activity, theoretical investigations of the process of confectioning with new forms of garment production in terms of outsourcing.