Forestry in Russia always was between Scilla and Haribda, that is between the civil servants and industrialists. The formers until now export the huge wood ground areas of country, and seconds behave as distraught wolf in fold by the Krylov fable.

Five venerable scientist academicians have addressed to V.V. Putin «with the request to pay attention to wood condition» [1]. In their request serious contradictions in wood science at once strike the eye. Therefore (what sighted person, is those also businessman) even a word «a wood» pundit use just so slovenly, that is not on nous, as it is noted in the text of enaction № 5 of Wood code.

In fifth article of Russia Wood code definition of wood as ecosystem is affirmed for the first time by the main priority, and understanding of wood as natural resource is delivered on the second place. Here between these concepts through union «or» fast a return to understanding a wood only as vertically standing timbers has taken place. Even in mentioned article [1] collocation «cut wood» is used, though the use by these academicians in the articles more than 30 explanations of this word outgoing still from the V.I. Dal dictionary should be not absolutely convenient. We interpret by students of wood specialities, that the wood is ecosystem, nucleus of which is stocking with growing trees. However as soon as we communicate with the industrialists, then we pass to the simplified slang of the consumers, that we fell, haul timber, log etc.

At the same time, in natural resources of country a place to wood which else almost 40 years before UNESCO and FАО UN considered only on the seventh place in succession of world wood availability, is not until now certain [2]. The use by trees as stemwood source hereafter will be and in Russia on the seventh place: oxygen, water, foods, soil, climate, fauna, wood. However, after acceptance of Wood code since 01.01.2007, Soviet technical rules of timber harvesting as sticks fast were copied, and, thereby, the management of forestry again has appeared at a level of the 20-th years ХХ centuries when the doctrine of a mass statistical material of stemwood taxation predominated.

In order to pass really on ecosystem thinking by the wood experts, in the beginning it is necessary to understand the japaneses, instead of finns or canadians, on what the authors of the circulation to government insist. Then, in 15-20 years of changes and in wood science, definition of a wood as eco-system, nowadays only declared in the Wood code, and without worthy scitech and landscape and ecological support can become primary. Main principles of the developmental approach to a research of main wood production group management dynamics (import, production and export) in 31 countries selected on the tendency of wood square growth from a total number of states (182 countries of the world) were showed in the book [2].

The special place in the world takes Japan wood business as a forerunner of the future in all world wood policy, technology of management by woods and realized modernizing of wood exploitation. Further inconsistencies in a comparison of the ground areas with wood arrays at the Japanese never arose. All this is one whole, Japan concerns to their territory as to one wood-meadow.

Wood production group ranking. Wood production groups on a modification of fractional wood raw material and semis structure is be distributed under the following order of preferability:

1) sticks - large tree trunk parts;

2) sawn wood - along-the-grain stick parts;

3) cauls, in which factions of xyloid substance as wood particles of chip, shredding (repeatedly crushed chip) and (or) spill (including cooms as elements of laminated asunder on wood spill fibrils) are used;

4) paper, including a carton, cellulose and misc., that is wood production group, in which the wood fibrils and their pieces are used (therefore area of primary support expands for limits of a growing wood and includes ligneous parts of agricultural and wild plants).

This ranked number of wood production groups is classified on a physical indication of element diminution from a tree trunk (stem), its parts (sections or merchandise as functionally certain sections) up to fibrils from sclerotic cell of any plant kinds. At that first two wood production groups concern to wood monolith, and third and fourth groups - to disintegrating wood.

The less fractional raw wood structure, the more industrial possibilities of use by the cut trees as activest wood exploitation component. Therefore increase in output of paper production and rundown of cauls, sawn wood and furthermore sticks is the main tendency of timber trade in all over the world on nearest 50 and more years (we heuristically suppose, that this tendency of development will be saturated technically and technologically in all countries up to an extremity of XXI centuries, and then century of a heavily wood replacement by other artificially created material kinds will come, however use of wood raw as renewable source will not be stopped never).

Each group having higher number (or lower fractional structure of wood in finish products) has the higher status.

The doctrine of transition on application of wood fibrils. In the world only two countries have approved in second half ХХ century as best workers of XXI century. During realization of national longterm project (on 2010-2040 years) «Russia: Forestry and Agribusiness» the experience of Sweden and Japan should be applied in scales of Russia since 2015-2020 years.

However some subjects of Russian Federation, in particular having a high level of health resort business and having recrations as large woodlands or the territories, on which there is a set of reserves and national parks, quite can begin realization of this doctrine passing on application of wood fibrils.

Sweden. This country in 1961-1960 years, as well as all european countries, sharply has risen production of wood cauls, trying to overcome production of a paper and carton on buildup. In 1971-1975 years perception of their national way in wood exploitation unlike from German happened.

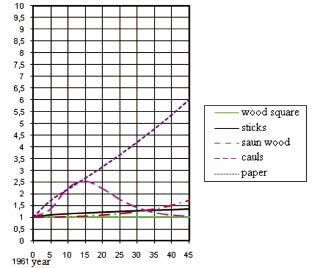

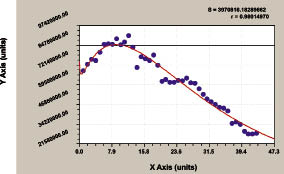

The comparison of the graphs on fig. 1 shows, that since 1975 year Sweden has passed on application mainly of wood fibrils.

Totally Sweden has gone on Finland way (once again we shall remark, that the Finland forestry has injured cheap Russia raw wood) and, eventually, has overtaken it. Overall production for 44 years was changed under the biotechnical law justified prof. P.М. Mazurkin, so, that the level of 2004 year has become equal to a level of 1961 year. It also is a realized turn to the new doctrine of technologies based mainly on wood fibrils.

Fig. 1. The graphs of relative wood production dynamics in Sweden

Sawn wood production tempos has become to overshoot sticks production tempos, that is the technology of sticks buck has changed cardinally (it is necessary still to take into account, that, as well as all over the world, from year to year quality of woodlands is as a natural result worsened in matter of high-quality wood; it is senseless to compete here with natural forces).

The swedes have created fundamentally new system of machines and equipment for sticks buck on boards. This experience needs immediately to be open up, by purchasing not only machine tools and equipment, but also machinebuilding plants.

Sweden «has wiped eyes» USSR. Upon completion of the Great Patriotic War many industrial plants making wood-working equipment, in particular plants on production of rasp machines of a type «Kambio» were exported from Sweden. The plant in Petrozavodsk more than 50 years was made this type of rasp machines, but and could not create fundamentally new equipment. And the swedes, by accepting the memorandum of full neutrality in «cold war», fast have adjusted issue of various sets of rasp machines, which are nowadays distributed all over the world. The destiny of many technical innovations, taken by us, in forestry from other countries is those. Nevertheless it would be very desirable to hope, that Russia can create not only system of forestry, successful distributed on the subjects of Russian Federation, but also centralized wood and together agricultural mechanical engineering. The experience of Sweden is rather useful to many rural and richly wooded regions of Russia, but does not approach to sparsely wooded regions.

However in Sweden, in difference from Russia, the wood squares because of territory defect (as well as Japan) are limited. It explains higher production tempos of sticks on comparison with growth rate of wood square.

The longterm forecasts for Sweden on forestry are not absolutely consolatory. Russia should take advantage of it to the full sharply by reducing export of sticks and saun wood and by adjusting at itself production of cauls, paper and carton.

Japan. This country has appeared most highlydeveloped not only in forestry, but also in a wood control and exploitation. Certainly, only the few of the above countries widely declare and advertise their strategic purposes. Japan is here again unique by the patent system and people attitude to innovations. Almost not having of their natural resources, first of all of petroleum, gas, gur coal and ore mineral, nevertheless, Japan is one from most highlydeveloped countries.

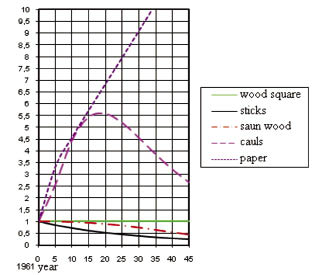

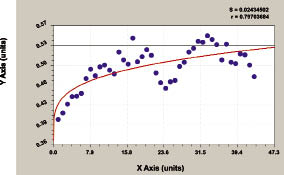

The Japanese phenomenon also was brightly exhibited for past 44 years in forestry (fig. 2). At once we shall remark, that the Japanese experience of forestry management to many Russian Federation subjects will be «too tough». From the schedules in a fig. 2 it is visible, that wood square in Japan for past 44 years almost was not changed. It is necessary to mark, that the population in Japan has become compared with tree number in their woodlands. However it has no an effect for a competitive wood extermination in agriculture favour (that cannot be told about agricultural Russian Federation subjects).

Japan experience is invaluable for a world civilization, as in 150-200 years hodiernal difficulties of Japanese residing will be characteristic for almost all countries (Russia can not indefinitely constrain demographic rush on the territory of peoples from congested nearborder countries; this tendency is already nowadays visible on sharp amplification of Chineses in Russia).

Japaneses were constrained sharply to reduce sticks production to save up at adequate level tree number and to not reduce wood square. It, certainly, almost automatically has reduced in saun wood production volume decrease. Thus, the solid wood product volumes have decreased also as the years go by. Unfortunately, the statistical data on nonwoody wood exploitation are unknown. It would allow to compare use tendencies of seed grains and fruitery, needles and foliage, rind from own Japan woods.

Comparison of the graphs of production of cauls and paper is the following remarkable instruction on good management by wood exploitation in Japan. Within 12 years, that is during 1961-1973 years, wood boards production growth rate have reached growth rate of paper and carton production. Or else, the Japaneses went in a channel of the world tendency of primary issue and circulation of wood boards (as it has taken place in Germany and then almost in all Europe).

Fig. 2. The graphs of relative wood production dynamics in Japan

In USSR this style has come only in an extremity of the 60-th years, and that, as the further practice has shown, in main only as the theoretical researches (researches in the beginning of the 70-th years about accessible distances of chip production were fashionable; researches about optimum distances of skidding and straight removal of cut epigeal tree portion with limbs for detailed primary processing in the lower forest yards were conducted).

In Japan since 1973 year process of a realized turn from production of wood boards was begun. Even this fact specifies that in Japan strategic forestry researches be ordered. And Soviet scientists understood in the contradictory declarations of fateful party congresses. For want of it the statistical researches didn´t develop (it was impossible to show for people cyclical slack periods and runups, the people should see only steady growth), that has reduced in the issue inevitably in loss of management by economy. Even the winged aphorisms of a type «economy should be economical» didn´t rescue in strategic wood management and wood exploitation.

Since a 1980 year in Japan the sharp recession of production of wood boards is observed. And the growth rate of paper and carton production was increased. To save this tendency in Japan it is necessary to reduce production rates of wood fourth group production. Russia can fast adjust in east country regions paper and carton production and within 5-8 years partially will replace Japan in the Asian and Australian wood production market. Therefore purchasing of Japanese technologies will allow bringing up Russian wood exploitation on Far East up to a world level. Strategic Russia advantage is that the Russian woods grow on its territory.

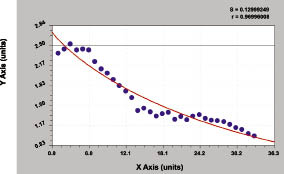

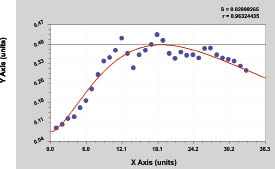

On fig. 3 it is visible, that the Japan trend promptly has decreased almost in 3,5 times. For want of it wave component (the difference between points and line) calms down.

The amplitude decrease of oscillatory perturbation always shows control quality. In the given example it concerns to management by dimension of sticks since 1961 for 1994 years. The significances of statistical parameters such as the variance equal to 0,13 m3/ga and the correlation coefficient equal to 0,96996 for the formula indicated as the law of exponential loss are indicated in a right upper angle of fig. 3.

Fig. 3. Dynamics of specific extraction of sticks from Japan woods

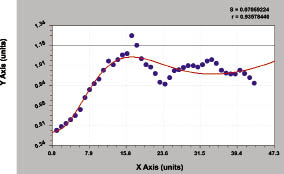

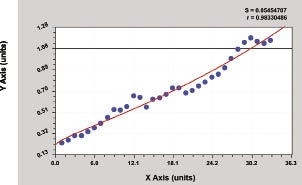

On data of ООN (the fig. 4) is received, that Japan sawed per some years more boards from one cubic meter of sticks.

This example clearly shows of forecast untrueness of former USSR Gosplan on a specific output of wood production from one cubic prepared wood meter. Certainly, it is possible to refer that in USSR the import of sticks was insignificant, however it does not change the essence of too «rectilinear» methodology.

Fig. 4. Dynamic of specific buck of prepared sticks in Japan

Dynamics of ready sticks in Japan. In the beginning we shall define ready sticks volume in country. In the first case it can be equal to import for want of own sticks production (for sparsely wooded and unwood countries and subjects of Russian Federation). In the second case ready volume will be equal to a difference between import and reexport of sticks, and in third the most general case it will be equal be expression «import + production - export».

Let´s remark, that similarly it is possible to consider wood square. The import of a wood specifies exploitation of another´s woods. For example, many developed countries take plots in Africa, Southern America in longterm concession. Imperial Russia actively attended by wood export, for example, selling of England large wood squares in the Pechora pool.

To an extremity of the 60-th years of the last century Japan has understood a limit of the growth on volume of sticks production, which, certainly grew because of rate magnification of wood import from Russia and other countries of Southeast Asia. Then there was a realized turn (fig. 5) to decrease of volume ready sticks.

Fig. 5. Dynamics of ready sticks in Japan

Japan has passed on a new forestry development stage, has become to increase wood square and to reduce production of whole timber as sticks and saun wood. For past 35 years, by a 2004 year, volume of ready sticks in country has decreased in four times.

Buck of ready sticks. This process is more authentic on a comparison with buck of prepared sticks, as takes into account its import (was not characteristic for USSR and will not be main for Russia). However for Japan and other consuming sticks countries production and export are important (USSR, and after it Russia have a huge share of all world) export of raw wood). The low sticks buck share shows that in country sticks extensively is applied in the coarse state in undertaking and other branches of national enterprise. (In our country always fences of building platforms were built and are built from highquality wood as well treated eaves boards, and the furniture is produced from harmful raw materials).

Ready sticks in this country is bucked actively. By a 2004 more than half of volume ready sticks (fig. 6) is bucked on saun wood. At the same time from distribution of points it is visible, that as the years go by the wave perturbation of an investigated parameter has amplified.

Fig. 6. Dynamics of specific buck of ready sticks in Japan

Per the first years XXI centuries noticeable ready sticks buck recession are observed.

Specific production of boards. There is a constant a previous history at the majority of countries, which is determined by the first member as constant number of a statistical model. This fact specifies that the branch of production of boards as a whole is rather pioneer. It has arisen 500 years back. Production of sticks is most ancient branch (not less than 10 thousand years), then there was a production of boards and furniture squares in ancient Egypt (5-6 thousand years back).

The small oscillatory perturbation observed on actual points in a fig. 7, show about successful strategic management by the Japaneses not only their woods, but also another´s import deliveries of raw wood for production of cauls. Therefore here it is possible to be learned to much in particular to logistics of wood exploitation.

Fig. 7. Dynamics of specific production of wood boards on wood hectare in Japan

From items of the theory of statistical modelling most surprising in the graphs in a fig. 7 is that the oscillatory Japan forestry perturbation amplification happens only during realized turn to decrease of production, in particular of wood boards. This fact also proves excellence of wood production control in Japan. For USSR, and the more so for Russia, the oscillations with vast unguided amplitude are characteristic, and in a fig. 7 the precise work on forecasting for the far future of forestry parameters is visible.

Since a 1980 year the Japaneses almost twice have reduced production of wood boards, ever more being guided on the world market on production from wood fibrils.

The own wood board production volume decrease tendency will proceed, apparently, 20-25 years, that is up to 2030-2035 years. Russia can make such realized turn only by a 2040 year. Therefore it is necessary to export to Japan wood boards of excellence, for want of it sharply reducing deliveries of sticks and sawn wood. Such strategy completely coincides Japan plans.

Specific paper and carton production. Paper production has arisen in ancient China more than three thousands of years back. However for country majority this group of furnish is simply technically very heavy. Russia has missed own machinebuilding industry creation chances for the issue of papermaking machines and equipment. On data of fig. 8, the graph of a trend is almost linear, that is steady paper and carton production growth is observed (however direct line equation cannot be applied, as it contains two components). For want of it the wave perturbation is minor and also has long periodicity.

Fig. 8. Dynamics of paper and carton production on wood hectare in Japan

If at the moment of USSR breakup specific paper and carton production is equal to 0,01 t/ga (in 1961 year this share was many times over less), on a comparison with Japan on the normative of wood exploitation Russia falls behind not less than in 110 times. From the graph in a fig. 8 also it is visible, that since a 1988 year Japan has exceeded paper and carton production norm in 1,00 t/ga.

Thus, perspectives of Russia are huge. By 2040 year it is quite possible to increase paper and carton production in our country at 60-80 times. It will require also origin of a mechanical engineering. For Russia with it´s the unpredictable past even for past 15 years of transitional development stage to market economy the own experience has appeared antiscientific. It has become too simplified because of forestry rule discussion to management «on concepts» (for example, the wood is understood only as sticks in words «to cut a wood», «to log», «to convert a wood», «to sell a wood», «to purchase a wood», etc).

In the total even the state forestry management in Russia does not correspond to prof. G.N. Morozov doctrine founder school about a wood. Prof. М.М. Orlov ideas about economic wood management completely are reduced to ultimately to stump sale, which, as a matter of fact, provides not sale of raw wood, and reimbursement of the future costs on stump extraction, processing of wood soil and plantlet fillingup (dropping) for resumption of felled crop.

The absence of authentic statistical information for continuous period does not allow comparing Russia to USSR, therefore it was necessary to address to FAO ООN data for period since 1961 year for a 2004 year. Unluckily on unknown by us information about wood square since a 1995 year till the present time did not have.

Only comparative dynamics for past 44 years has allowed understanding behavior illogic of USSR and hereinafter of Russia in wood policy and technology of forestry. In 1994-1996 years it was possible to develop cultivation concept of new crops and wood exploitation in Russia. The time of the 22-nd solar activity cycle irrevocablely was lost. All the 23-rd cycle (and also high-power on Sun in-fluence to mankind) already have lost.

References

- The wood requires a master´s hand / D. Martynkina // Week arguments. - 2009. - № 43 (191). October 29.

- Mazurkin P.M. Wood and agricultural Russia and world dynamics of wood exploitation: scientific issuing / P.М. Mazurkin. - Yoshcar-Ola: MarGTU, 2007. - 334 p.

The article is prepared and is published for want of to 3.2.3/4603 МОН Russian Federation grant support.

Библиографическая ссылка

Mazurkin P.M. REALIZED TURNS IN WOOD BUSINESS OF JAPAN // European Journal of Natural History. 2010. № 6. С. 33-42;URL: https://world-science.ru/ru/article/view?id=21094 (дата обращения: 06.02.2026).