Biodiesel is an environmentally friendly alternative fuel source that comes on the heels of refined products. The process of obtaining biodiesel fuel occurs during a chemical reaction of transesterification. In this reaction, vegetable oil or any other source of triglycerides reacts with monoatomic alcohols in the presence of a catalyst, forming monoalkyl esters of fatty acids (biodiesel, MEFC) and glycerol. Biodiesel or biodiesel is a liquid motor biofuel that is a mixture of monoalkyl esters of fatty acids. Biodiesel is obtained from triglycerides (rarely free fatty acids) by the reaction of transesterification (esterification) with monatomic alcohols (methanol, ethanol). The source of triglycerides can be various vegetable oils or animal fats.

The environmental aspect and government support programs are the main factors in the development of biodiesel production. Meanwhile, the production of biodiesel in the EU and Russia varies significantly.

The purpose of this article is to consider the development of the biodiesel industry and the production of biofuels in Russia and Germany.

Materials and research methods

The article is written on the basis of empirical material from modern scientific technical and journalistic sources in Russian, German and English. Research methods are an actualization of the problem in modern foreign and Russian scientific literature and a comparative analysis of the technical and economic situation in Russia and Germany. These research methods are relevant for the development of professional competencies of top-level specialists in the field of agriculture.

Research results and discussion

Biodiesel is the most well-known biofuel in EU. Around 1.8 m. tonnes of biodiesel from vegetable oils are consumed in Germany each year. This corresponds to roughly two-thirds of German biofuel sales.

Raw materials

For many people, ‘biodiesel’ calls to mind blossoming fields of rapeseed, and in Germany it is indeed primarily sourced from rapeseed. However, other vegetable oils and also used edible fats and animal fats can serve as possible alternative starting materials. Whereas, for climatic reasons, in Central Europe it is rapeseed that dominates in the production of biodiesel, in Asia it is normally manufactured from palm oil and in America from soya oil. Biodiesel sourced from recycled materials is also gaining in significance. Compared to biodiesel obtained from cultivated biomass, it is primarily the lower GHG emissions that are stated as an advantage of biodiesel sourced from used edible fats.

In EU, biodiesel is mostly obtained from rapeseed, as a native raw material. The cultivated area, almost constant in recent years at around 1.4 m. ha, lends emphasis to the great significance of rapeseed cultivation in Germany. Manufacture of edible oil, margarine, etc. requires a rapeseed cultivated area of around 300,000 ha. Industry accounts for around 120,000 ha, using the product as a material. Yet the lion’s share that remains, around two-thirds of domestic rapeseed area cultivated, is available to biofuel production and, where applicable, to export.

For a chemist, biodiesel is in fact vegetable-oil methyl ester, or respectively it is characterised as fatty acid methyl ester (FAME). The abbreviation RME is also established for rapeseed-oil methyl ester. Thus biodiesel is not to be confused with vegetable oil but is manufactured from it.

Manufacture

In Germany the first facilities for biodiesel production were set up in the 1990’s. It is manufactured by transesterification of vegetable oil with methanol: for this, veg-etable oil is mixed with methanol in a 9:1 ratio. To accelerate the process, 0.5–1 % of a catalyst (sodium hydroxide or potassium hydroxide) is added and the mixture is stirred at temperatures of 50–80 °C for several hours. In the chemical reaction that follows, the vegetable-oil molecule, consisting of glycerin and three fatty-acid chains, is split. The trivalent alcohol, glycerin, is replaced by the monovalent alcohol, methanol, so that the fatty acids combine with methanol to form biodiesel. What remains at the end of the reaction is raw biodiesel and raw glycerin in two easily-separable phases.

So as to attain biodiesel of the desired product quality, raw biodiesel must go through several steps of processing. The same applies to the glycerin, an alcohol that finds use in many business sectors, such as pharmaceuticals, the food industry and the oil sector, and is normally manufactured synthetically [1].

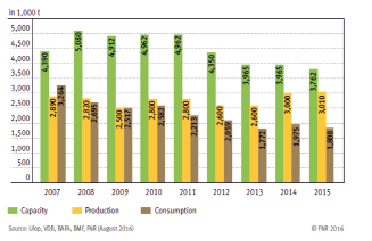

Figure 1 shows the dynamics of production and sales of biodiesel in Germany (fig. 1).

Fig. 1. Development of Biodiesel. Production and sales in Germany [2]

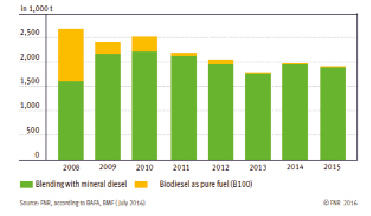

Fig. 2. Biodisel (pure and mixture) sales in Germany [3]

Properties and quality of the fuel

For the use of vegetable-oil fuels, the engine needs to be adapted to the fuel; in the case of transesterification to form biodiesel, the fuel is adapted to suit the engine. As regards viscosity and its ignition performance, it has similar characteristics to fossil-based diesel. Through using additives, as is also customary for traditional fuel, the product is made suitable for winter use: as low as –20 °C, biodiesel can be used without problems. The lubricity of biodiesel, important to keep wear-and-tear on the engine low, is even higher than that of fossil fuel. By contrast, the energy content per liter is somewhat lower; this can lead to additional consumption of up to 5 %.

In 2003 the requirements necessary for fuel quality were established in the DIN EN 14214 norm, valid throughout Europe. The integration of the latter into the 10th Federal Emission Protection Ordinance (10. BImSchV) also anchors these requirements in national law. If biodiesel is offered at public fuel-stations, it is obligatory to make known the quality of the fuel, according to the norm, by attaching the DIN sticker to the fuel-pump column.

The oil companies add up to 7 % biodiesel (B7) to traditional diesel, without any need for the vehicle-holder to take any technical prerequisites into account. To comply with the norm for fossil-based diesel fuel (DIN EN 590), the mineral-oil manufacturers may only add biodiesel that in turn corresponds to the biodiesel norm DIN EN 14214. On the fuel-pump column, a sticker stating «Contains up to 7 % biodiesel» directs attention to the so-called B 7-fuel.

As is customary for petrol and diesel, additives are also put into the biodiesel in order to improve its properties. Information on quality-assurance with regard to biodiesel is offered by the Association Quality Management Biodiesel e. V. at www.agqm-biodiesel.de an [1].

Approvals for biodiesel vehicles

For use of biodiesel as a pure fuel or in mixtures with a biodiesel proportion of > 7 %, approval by the manufacturers is necessary. In non-approved vehicles, biodiesel’s properties, similar to those of solvents, can lead to problems; where applicable, the product can attack plastic and rubber components, such as seals and petrol-ducts in the engine. Overviews with regard to vehicle approvals for biodiesel (B 100) in agricultural and forestry use, but also for the commercial-vehicles sector more broadly (B 100 and B 30), can be accessed on the internet pages of the Union for the Promotion of Oil and Protein Plants (abbreviation: UFOP)) at www.ufop.de. Likewise, when retrofitting particle filters it is essential to ensure that the filter and vehicle are approved for biodiesel use [1]. Figure 2 shows the sales of pure biodiesel and a mixture of biodiesel with traditional diesel (fig. 2).

Market presence/use

Supported by complete tax-exemption, the history of biodiesel in Germany began with the sale of pure fuels – also known as B 100. Vehicle fleets tanked up their commercial vehicles with biodiesel and numerous car models obtained approvals for use of this fuel. The biodiesel market in Germany changed with the stage-by-stage introduction of tax from mid- 2006 and with the biofuel quota, created as a countervailing measure. Higher raw-material prices and increasingly demanding requirements regarding emissions adversely affected sales of B 100, such that today biodiesel as a pure fuel comprises less than 1 % (around 3,000 t) of total biodiesel sales – more than 99 % of the total consumed is added directly to diesel fuel by the oil companies.

At 3 m. tons, biodiesel production exceeded domestic sales of 1.8 m. tons in 2015. In this context the manufacturers in this country – with a production capacity of 4 m. tons in all – primarily use native raw materials. Accordingly, in Germany in 2015 around 650,000 ha of rapeseed were used for the production of biodiesel and vegetable oil. [4].

Environmental aspects

Through the use of 1.8 m. tons (t) of biodiesel in Germany in 2015, more than 1.8 bn. liters of diesel fuel were replaced and around 2.1 m. t of greenhouse-gases saved. Thus biodiesel’s contribution to the protection of resources and of the environment is undisputed. That contribution will further in crease because it is to be expected that the latest requirements of the sustainability ordinance (among other things) will generate further optimizations in biofuel production.

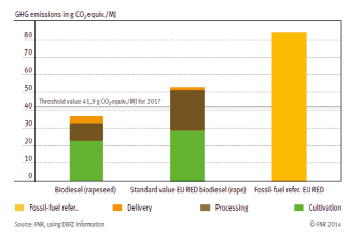

The production of biofuel causes emissions, along the chain of manufacture and supply, that are primarily to be attributed to the activity areas of cultivation and processing. The latest targets stipulate a GHG saving of 35 % in relation to a reference value for fossil-based diesel fuel; from 2018 the relevant value is raised to 50 %. How many GHG emissions the biodiesel saves in the individual case can be calculated for one particular facility or via the standard values from the «EU Directive on the Promotion of Energy from Renewable Sources». According to this, biodiesel made from rapeseed saves at least 38 % of GHG compared to the reference fuel; biodiesel from sunflowers even saves 51 % (fig. 3).

It is the cultivation of biomass, above all, that provides potential for savings. Thus an optimized deployment of fertilizer and the taking into account of average rapeseed yields (that are by now further increased) positively affected the GHG balance. The DBFZ calculates that, in practice, the emissions in the case of biodiesel sourced from rapeseed could therefore be roughly one third below the conservative EU standard value [4].

In Russia, there is no unified state program for the development of biodiesel, but regional programs are being created, such as the Altai regional target program “Rapeseed-biodiesel”. The Association of rapeseed oil producers has been established in the Lipetsk region.

It is planned to build plants for the production of biodiesel in the Lipetsk region, Tatarstan, Altai territory, Rostov region, Volgograd region, Oryol region, Krasnodar region, Omsk region, and Novgorod region [6].

Fig. 3. GHG EMISSIONS: BIODIESEL FROM RAPESEED [5]

Production of biodiesel from algae

The most promising source of raw materials for the production of biodiesel is algae. In 2006, several companies announced the construction of plants for the production of biodiesel from algae:

– Global Green Solutions (Canada) based on Valcent Products technology (USA) – production capacity of 4 million barrels of bio-oil per year;

– Bio Fuel Systems (Spain);

– De Beers Fuel Limited (South Africa) by Greenfuel Technologies Corporation (USA – production capacity of 900 million gallons of biodiesel per year (algae + sunflower oil)

– Aquaflow Biomic Corporation (New Zealand) – production capacity of 1 million liters of biodiesel per year.

Russian scientists from the Joint Institute of High Temperatures (Russian Academy of Sciences and Moscow state University) have developed and successfully tested a plant for the conversion of biomass to bio-gasoline. The resulting fuel, mixed with conventional gasoline, was tested in a two-stroke internal combustion engine. The new development allows you to process all the algae biomass at once, without drying it. Previously used attempts to obtain bio gasoline from algae provided for a drying stage, which in terms of energy consumption exceeded the energy efficiency of the resulting fuel. Now this problem is solved. Fast-growing microalgae are much more productive in converting the energy of sunlight and carbon dioxide into biomass and oxygen than conventional land plants, so getting biofuels from them is very promising [6].

The slow development of the biofuel market in Russia is due to a number of interrelated factors. First of all, our country, which today has the richest oil reserves and is the world’s first and second exporter of this raw material, does not have an urgent need to search for alternative energy sources.

According to the USDA, biofuels in Russia produce about 5 % of heat and 1 % of electricity, and the share of transport running on bio-fuel does not reach 0.5 %. The fact is that any car can use gasoline with an admixture of bioethanol up to 10 %, and switching to a mixture with a higher content of this fuel, up to 100 %, requires a mechanism with a flexible choice of fuel. The transfer of the domestic fleet from diesel to bio-fuel may amount to a third of the total cost, which is not economically profitable at the moment.[7].

However, the Russian bio-fuel market has a future in agriculture. According to Alexey Ablaev, President of the Russian National Biofuel Association, the main driver of the development of the bio-fuel market in Russia will be the need to increase domestic demand for agricultural products. [7].

Bioeconomics in general and biodiesel production in particular are promising areas for agricultural development. [8]. Potential suppliers of raw materials for the production of bio-combustible in Russia are farms and collective farms. If such enterprises are equipped with the necessary equipment and trained specialists, domestic farmers will be able to self-supply fuel for their agricultural work, which will have a positive impact on the price of finished products and increase the competitiveness of the enterprise.

Conclusion

Biodiesel, as renewable biofuels, offer the chance to lessen the dependence on and consumption of petroleum and to secure the supply of fuels. Economic changes in the field of biodiesel fuel production can benefit rural areas. The agricultural cultivation of energy crops and their recycling is a way to sustainable development of agricultural enterprises. In conclusion, we note the following: a decisive economic factor for the development of biodiesel production in Russia is the reduction in its cost compared to conventional diesel fuel. Until this happens, large-scale biofuel production is unlikely. Reducing the cost of raw materials, in particular vegetable oil, based on increasing the productivity of agricultural enterprises can help solve this problem. Algae are another alternative and very promising raw material for biodiesel in coastal areas.

Библиографическая ссылка

Нестерова Т.Н., Журавлева Н.Н. БИОДИЗЕЛЬНОЕ ТОПЛИВО В ГЕРМАНИИ И РОССИИ // European Journal of Natural History. 2020. № 4. С. 58-62;URL: https://world-science.ru/ru/article/view?id=34118 (дата обращения: 02.02.2026).