The data of scientific researches show that many industrial enterprises are insufficiently provided with safety devices, sanitary facilities and devices, personal protective equipment at present days [1].

The inadequate state of working conditions, the prevalence of heavy physical work, disruption of working and resting modes, low coverage and poor quality preventive medical examinations, liquidation of health units and dispensaries, and a drastic reduction in sanatorium and spa services are the cause of health problems for workers [2].

The state of working conditions of employees is directly reflected in the indicators of occupational morbidity and disability. Despite the fact that occupational diseases are less common than other major diseases, their social significance is great, since they affect a considerable number of people of working age, often they are hard and cause disability [3].

According to WHO, over 100 thousand chemicals, about 50 physical, 200 biological factors, about 20 unfavorable ergonomic loads can be harmful factors, increase the risk of accidents, diseases, stress reactions, cause dissatisfaction with work. According to the WHO European Center for Environment and Health, in countries with a highly developed industry, only physical stress negatively influence on 10-30 % of workers [4, 5].

Thus, the study and assessment of the impact of harmful production factors on the health of industrial workers, including the life expectancy of men as one of the indicators of sustainable development, is actual from the point of view of the main provisions of gender policy (Decree of the President of the Republic of Kazakhstan No. 216 of November 14 2006).

Therefore, the purpose of the study is to assess the impact of harmful production factors on the health of industrial workers.

Research results and discussion

The results of the questionnaire survey of 1,110 SSMPE workers made it possible to identify that more than 65.9 % of the shift time was spent on basic types of work.

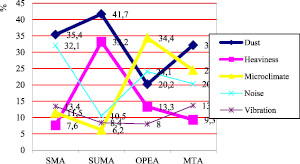

Among 35.4-3.7 % of the interviewed mining equipment drivers at the quarry believed that the decline in the quality of labor productivity was due to the high concentrations of dust in the air of the work area and more than a third (33.1 ± 4.1 %) of the interviewed drivers pointed to impact of intense noise and 13.4 ± 3.9 % on the impact of general vibration (Fig. 1).

In underground mines, more than 41.7 % – 6.1 % of the surveyed machinists servicing mountain underground equipment believed that the dust factor affects on the working condition. More than a third of the 33.2-6.1 % of the fasteners, whose work activity is related to the fastening of the bottom of the mine and the delivery of fastening materials, believed that the severity of labor influences on the working conditions.

An analysis of a questionnaire survey of 440 workers at the concentrator factory revealed that among interviewed machinists of the ore enrichment equipment believed that among the production factors, the air temperature of the cabins (34.4 %) and the dust factor (30.27 %) have a greater effect on working capacity.

Fig. 1. Subjective assessment of the influence of production factors on work efficiency

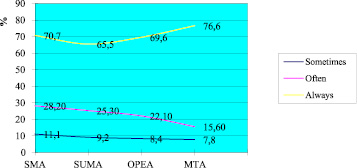

Fig. 2. Assessment of the performance of labor by the SSMPE workers in the forced position of the body

The quality of the performance of production assignments in 35.3 % depends on the psychoemotional stress associated with the management of equipment, where work requires focused attention and hearing.

Drivers of heavy haulers, bulldozers, motor graders believe that the working capacity is affected by the dust and gas factor (32.2 %), temperature (24.5 %) and noise (20.3 %).

As can be seen from Fig. 2, the performance of labor operations by miners was mostly accompanied by a forced position of the body.

It should be especially noted that more than 76.6 ± 4.2 % of the interviewed ATU drivers and 70.7 % ± 3.2 % of the quarry drivers, 69.6 % ± 2.1 % of the machinists of the concentrator factory and 65.5 % ± 3.7 % % of the drivers managing underground equipment work more than 47.7 % of the shifting time in sitting position, with torso turns to the side and forward. More than 70.7 ± 4.0 % of drivers managing mining equipment performed production tasks at a fast pace, constantly in the “sitting” position. The rapid switching of the control panel levers is due to the rapid response of the sensorimotor analyzers and motor analyzers.

In the opinion of a third of the surveyed fasteners, the fixing of the intrabillage space was carried out in the standing position, with the body torsions forward and sideways and are associated with a significant postural strain of the muscles of the back and lower limbs.

About 64.5 ± 4.2 % of the interviewed electricians noted that their work was accompanied by a forced position of the body during performing repair work using hand tools.

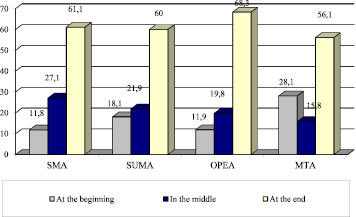

Fig. 3. Assessment of the feeling of fatigue of SSMPE workers during the working shift

In Fig. 3 it is visually shown that about 61.1 ± 7.2 % of the surveyed machinists of drilling equipment, excavator operators, drivers of heavy trucks on a quarry noted that at the end of the shift there was a pronounced fatigue, one third of the respondents (19.8 ± 7,3 %) – in the middle of the shift and only about 11.8 ± 6.3 % – at the beginning of the shift.

Over 60.4 ± 9.3 % of surveyed underground ore extraction miners noted marked fatigue at the end of the working day. In the opinion of half of the surveyors (56.1 ± 3.3 %) sinkers and fasteners, the rapid pace of work with the necessary technical materials led to severe fatigue in the middle and a decrease in overall performance at the end of the shift.

In the opinion of 68.3-3.3 % of the surveyed crushers, screeners, bunkering workers, separators, the labor operations were performed standing, with the body torsed forward and to the side and are connected by a significant postural tension of the muscles of the back and lower limbs. That is, the workers of these professions attributed their work to heavy work and believed that the implementation of manual operations is more associated with significant dynamic loads on the muscles of the limbs and trunk.

About a third of the interviewed workers of ATU, namely drivers of heavy trucks and drivers of road machinery, believed that among the unfavorable factors of production, the high nervous and emotional tension of labor (20.6 % – 5.2 %) influenced the performance of production tasks. More than 56 % of the interviewed respondents believed that by the end of the shift, overall performance was declining.

When answering the question: “How do you assess fatigue”, about 42.5 ± 9.9 % of the machinists answered that fatigue is associated with high sensorimotor loads, both in the visual and auditory analyzers. The management of underground mining equipment is performed in 62 ± 8,9 % often “sitting” and the load is felt more on the spine 43,2 ± 3,1 %.

About a third of surveyed sinkers, fasteners and miners of the cut face noted that performing manual operations is largely due to significant dynamic loads on the muscles of the limbs and trunk.

Despite the general fatigue that felt during the performance of production assignments, more than 68.1 ± 9.7 % of the interviewed SSMPE workers noted that the lost strength is restored in 3-4 hours after the end of work.

The results of the questionnaire survey showed that more than 58.3 ± 9.7 % of the surveyed workers performed production activities at a rapid pace (Table).

Work from 71.7 % to 80.8 % was performed in standing position, with torso turning forward (from 43.5 % to 53.1 %) and aside (from 34.6 % to 45.4 %).The study of technological processes and the nature of labor of workers of the main sections showed that their work is associated with great physical load and nervous – emotional stress.

Assessment of the working capacity of miners of underground mining of polymetallic ores, %

|

Name of questions |

Variants of answers |

SMA (n-130) |

SUMA (n-360) |

OPEA (n = 440) |

MTA (n = 180) |

|

Rate of work performance |

monotone fast very fast |

10,3 ± 5,2 59,4 ± 8,4 30,3 ± 7,9 |

11,2 ± 5,6 59,1 ± 8,8 34,7 ± 8,5 |

9,7 ± 5,6 69,2 ± 8,7 21,1 ± 7,7 |

15,2 ± 6,2 58,3 ± 8,6 26,8 ± 7,7 |

|

Working posture |

standing sitting down half-sitting |

80,7 ± 6,7 10,2 ± 5,2 9,1 ± 4,9 |

72,4 ± 8,0 16,8 ± 6,7 10,8 ± 5,6 |

80,8 ± 7,4 8,2 ± 5,2 11,0 ± 5,9 |

71,7 ± 7,8 18,8 ± 6,8 9,5 ± 5,1 |

|

Body turns |

forward to the side backward |

53,1 ± 7,9 35,3 ± 5,8 12,5 ± 5,7 |

45,5 ± 8,9 38,5 ± 8,7 16,0 ± 6,6 |

43,5 ± 9,4 45,4 ± 9,4 11,1 ± 5,9 |

49,1 ± 8,7 34,6 ± 8,3 17,2 ± 6,5 |

When identifying the main, leading (specific and dominant) factors that affect health and life expectancy, the following results are obtained:

1) data of socio-hygienic monitoring of 1110 quarry workers revealed that 35.4 ± 3.7 % of the studied people believed that a decrease in working capacity is associated with exposure of high concentrations of dust in the air in the work area, intense noise and vibration. At the end of the shift, more than 75 % noted marked fatigue, lost strength recovered after the weekend;

2) more than half of 53.4 % of workers in underground mining of ore believed that the state of working capacity is more influenced by high level of dust in the air and the effect of intensive noise and vibration, the severity of labor (33.5 ± 2.1 %), unfavorable microclimate (13.5 ± 3.1 %);

3) one-third (39.1 ± 4.0 %) of the workers of the ore preparation assessed their health condition as good and (60.9 ± 10.1 %) were not sick at all during the past year. The prevalence of people with “poor” health levels ranged from 5 % to 26 % among workers in the main professions. At the same time, more than 19.6 ± 7.1 % of the respondents for the previous year were sick only 3-4 times.

Medical and preventive measures to improve health.

1. The main purpose of preventive examinations is to prevent individuals, with medical contraindications from working in the specific professions of ore production and the correct employment of people recognized as fit for work.

2. When conducting periodic medical examinations of workers with a shift work schedule, it is necessary to conduct an electro-cardiographic survey, as a method to identify hidden and obvious forms of cardiovascular insufficiency, as well as correct the revealed deviations on time.

3. For the timely diagnosis of bronchopulmonary pathology, it is necessary to conduct spirographic examination.

4. For the prevention of diseases of the upper respiratory tract, it is necessary to carry out alkaline-oil inhalation 12-14 procedures each time, with a break of 1-2 months.

5. For the prevention of dust diseases of the lungs consider the usage of antioxidants (vitamins – A, E, C).

6. To prevent the development of occupational diseases, it is recommended that a complex of therapeutic measures be taken – plant adaptogens, vitamins – antioxidants (A, C, E), a bacterial polysaccharide – prodigiosan or a yeast polysaccharide that have an immunocorrective effect.

7. To reduce the level of stress during the working process, it is necessary to limit the duration of significant static loads, respect the regulated breaks for eating and performing heavy work.

8. For the prevention of gastrointestinal diseases provide for the organization of underground hot meals and special vitaminised drinks.

9. Comply with the receipt of BOB by employees of particularly harmful professions. Keep the existing list of professions eligible for free milk.

10. Organize the psychological relief rooms to relieve psycho-emotional stress and provide relaxation procedures and rooms for cyclic physical exercises to strengthen the musculoskeletal system.

11. To maintain a high level of performance and reduce physical fatigue, it is necessary to correct the rationalization of work and rest during a shift depending on the category of work severity. A regulated break should be at least 20 minutes of a work shift.

12. The identification of the initial signs of diseases specific to this production, as well as functional disorders, will allow for timely conduction of treatment and preventive measures, especially in a sanatorium, and if necessary, to employ workers for easier technological operations.