In the EU countries, the development of the energy sector based on renewable energy sources becomes a state program. The European Commission and individual departments of EU countries created directives (development plans) and are taking concrete steps to implement these plans. In Russia, some steps are also being taken to develop the market for alternative heat power, but they are not regular. Meanwhile, the use of heat sources based on biomass is a very promising direction for the development of bioeconomics as a branch of the national economy as a whole. [1]. The purpose of our research is to review foreign and Russian information sources on the topic of “obtaining heat from biomass as a renewable energy source”.

Materials and research methods

The article is written on the basis of empirical material from modern scientific and journalistic sources in Russian, German and English. Research methods are a theoretical review of foreign language literature and comparative analysis of the technical and economic situation in Russia and Germany. These research methods are relevant for the development of professional competencies of top-level specialists in the field of agriculture. [2].

Research results and discussion

Heat from renewable energy sources (RES-T)

Heat is used in the residential, services and industry sectors of society for space heating and tap water production. Process heat is used in the industrial sector. Normally heat is produced by combustion of fossil fuels, but renewable energy sources can be used to provide heat with a low or neutral contribution to CO2 emissions.

In the RES-E Directive, the following definition of Renewable Energy Sources (RES) is applied:

“Renewable energy sources” shall mean renewable non-fossil energy sources (wind, solar, geothermal, wave, tidal, hydropower, biomass, landfill gas, sewage treatment plant gas and biogases) [3].

The European Renewable Energy Policy is based on the White Paper of the European Commission. It is a European community strategy and a concrete action plan. The goal of this strategy is to increase the share of renewable energy sources in the gross domestic energy consumption in the EU to 12 % already in 2020, and includes a timeline to address these challenges [3]. In order to produce thermal energy, various renewable energy sources manifest themselves in different ways. And not all sources are equally suitable for this. Solar, geothermal energy, biomass, landfill gas, sewage treatment gas and biogas are suitable for conversion into heat. From the listed sources landfill gas and wastewater gas are usually directly converted to electricity at burning place. Biogas is often used for further processing.

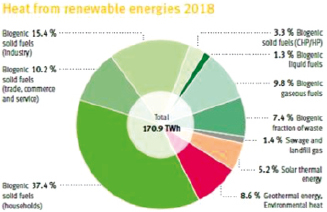

The three main types of renewable energy sources for generating heat are: biomass, solar energy, and geothermal energy (including ambient heat from heat pumps). The Federal Agency for renewable energy (Germany) provides the following statistics on heat generation in the EU from alternative energy sources for 2018 (fig. 1).

Fig. 1. Heat from renewable energy sources in the EU for 2018 [4]

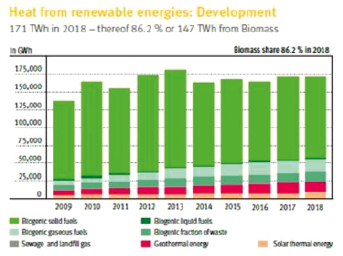

Fig. 2. Heat from renewable energy sources in the EU: development [4]

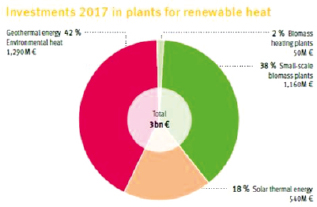

Fig. 3. Investments in plants producing heat from renewable energy in 2017 [4]

The following fig. 2 shows the development of alternative thermal energy in the context of various sources in the EU countries for the period 2009-2018.

Public investment plays a significant role in the development of this industry. Fig. 3 shows the financial investment analysis.

As we can see, with a total financial investment of 3 billion Euro. The total investment in plants based on biomass processing amounted to 40 % (2 % – biomass boilers, 38 % – small biomass boilers).

As for heat pumps, this is a somewhat inaccurate relation to renewable energy sources, since they still require the use of primary fossil energy (such as natural gas) or electricity in order to raise the surrounding heat to a useful temperature level. Therefore, some sources do not consider heat pumps as renewable energy applications, while other sources may refer to them as hybrid applications (partially renewable and non-renewable). The same applies to heat from waste incineration, which is often not considered a renewable energy source in a General sense, but certainly contributes to a sustainable energy situation and security of supply.

Let’s take a closer look at the state of Affairs with the use of renewable energy Based on biomass in the EU.

Main market segments for biomass heat are:

– Small scale space-heating application of firewood in traditional stoves and open fireplaces: By far the largest market. Casual and unregulated character does not allow for reliable statistics. The decline of traditional rural lifestyles is threatening the informal structures of fuelwood use. Often low energy efficiency of 20-25 % and questionable environmental merits. But cleaner and higher efficiency alternatives exist)

– Small scale space- and hot-water applications of modern biomass boilers. Emerging market (approx. 1 million installed in the EU). Fuel is usually pellets (with or without auto-feeder), wood logs, etc.. Energy efficiency in the 70-80 % range (on l.h.v.14). Relatively clean combustion. Larger installations used for heating of flats.

– Larger scale: Dedicated biomass boilers for district heating (DH). Fuels are hay, grass, peat, wood. Sometimes biomass is combined with waste. Small part of DH installations, esp. in Scandinavia. Also an alternative in converting coal-fired DH plants. Smaller installations used for block heating. Possibly interesting alternative in the modernisation/decentralisation of DH-grids in NACs.15

– Larger scale: Industrial heating boilers (e.g. from waste products in their own production; paper and pulp industry, sawmills, etc.)

– Larger scale: District Heat from biomass-fired cogeneration (CHP) plants. In the EU-15 more than 70 % of DH comes from CHP. Same considerations as above. In the NACs, the CHP share in DH can be as low as 25 %.

– Large scale: Biomass as additional mixing-fuel in coal-fired power plants, which then use their waste heat for district heating. Emerging as ‘greening’ strategy of coal-fired plants. Example: Applications were filed in the Netherlands for 4 such projects, saving in total 1.8 Mton CO2.16 Most merits will go to RES-E, but a part should be partitioned to RES-H as a heat outlet.

– Large scale: Biomass conversion to solid, liquid, gaseous (bio)fuels, which can consequently be used to produce – amongst other things—heat. Examples are pellets (e.g. from biodegrable fraction of waste), liquid biofuels for cars or industrial heating systems and biogas (from landfill, sewage, etc.)

As mentioned, reliable statistics are difficult to obtain, as a large part of the biomass heat production has a ‘casual’ and unregulated character. An extra difficulty arises from heat of ‘waste incineration’, which in some countries is classified under RES and in others is not [3].

Drivers and barriers

Important market drivers are:

– The existence of a solid fuel or oil boiler tradition. The major boiler markets (Germany, France, UK and Italy) all have extensive gas networks. It is not likely that households with gas boilers will tend to switch to biomass fuel. More potential for biomass boilers is found in countries without gas networks.

– Relative prices between fossil fuels and biomass fuels. Rising fossil fuel prices have shown to have an positive impact on sales of biomass boilers.

– The availability of biomass fuels. Networks for wood log, chip and pellet distribution are growing, for instance sales of pellets at petrol stations.

– Existence of incentives for installation of biomass heating. In Denmark, government subsidies have significantly boosted biomass boiler sales.

An important barrier to the uptake of biomass boilers is the higher investment costs of biomass boilers compared to conventional boilers (although the running costs might be lower).

Rise in biomass boiler sales is mainly foreseen in the higher output capacity areas (block heating etc.) and located mostly in the new accession countries. However, Germany also has a large potential (sales are expected to triple in the coming years) [3].

State of the industry in Russia

In Russia, the first initiatives to produce heat from biological raw materials started in 2009. A biogas plant was built in the village of Doshino, Kaluga Region. The raw material for it was green biomass. In a biogas plant, methane is released as a result of the fermentation of organic raw materials. Bacterial environment contributes to this process. Then biogas is burned. As a result of this process, heat and electricity are generated. A by-product is high-quality organic fertilizers that can be used later on in the fields of agricultural enterprises [5].

The most common raw materials in biogas plants in Europe and Russia are solid and liquid manure and silage. However, biogas can also be extracted from other types of raw materials, and not only on the basis of agricultural enterprises. Processing plants can supply food waste, feed residues for this purpose, utilities can collect biowaste. In most cases, plant materials for power plants are grown specially and systematically. These are corn, various herbs, sunflower, grain, beets, silage, etc. The plant mixture is fed into the bioreactor. It is a large insulated tank with a bacterial base, which is heated.

Biogas production is possible only if this device has an aerobic-anaerobic structure. Biogas plants operating on biomass can be profitable for the manufacturer. From the point of view of sustainable production, they significantly improve the environmental situation.

The main buyer of biogas plants in Russia is agricultural enterprises that process their own raw materials and waste and generate heat for their own needs. Contributing to the economy of enterprises is the reduction of environmental costs in the field of livestock complexes. The processing of hazardous waste usually takes up a significant part of the budget of farms and poultry farms. These enterprises are forced to spend significant funds on the export and processing of thousands of tons of manure that contains harmful substances. The soil at the places of manure storage is unsuitable for use for a long time. Moreover, state and municipal laws provide for sanctions and penalties for the disposal of harmful substances.

The benefit of using a biogas plant is obvious: the producer generates its own heat and solves the problem of waste disposal.

Corporation “Biogazenergostroy” (the BHPP) has begun the construction of a biogas plant in the village Romodanovskaya (Mordovia). Nowadays this is the largest project in the field of bioenergy in Russia: the capacity of the station will be 4.4 MW.

As raw materials, the station will use waste from cattle and beet pulp, the press service of the Corporation reports. The main suppliers of raw materials are SPK “Romodanovsky”, the nearby farms, as well as sugar factory. The heat generated at the plant is used for heating greenhouses located on nearby farms, as well as for drying and granulating organic fertilizers, which are a by-product of the biogas plant. The cost of construction of the station is 5-7 thousand euros per kilowatt. The total investment amount is 25-30 million Euro, provided of the Corporation “Biogazenergostroy” from their means, and with the involvement of Western funding [6; 7].

Conclusion

Biomass processing is a very important vector of the heat and power industry. Environmental factors (saving of fossil resources, the need for recycling and waste disposal) play an indubitable role in its further development. Economic factors are not so great at the moment and the development is possible only with the support of state programs and active state subsidies.